Introduction

Have you ever wondered what makes your electronic devices withstand harsh environments and varying temperatures? Ever pondered about the tiny yet powerful components that work tirelessly behind the scenes to ensure your devices function optimally? Or perhaps, you’ve heard the term ’94v0 circuit board’ being thrown around in tech conversations and wondered what it means? If you’ve found yourself asking these questions, then you’re in the right place.Let’s delve into the fascinating world of 94v0 circuit boards and uncover the answers to these questions.

A 94v0 circuit board is a type of Printed Circuit Board (PCB) that has been tested and certified under the UL 94V-0 Flammability Standard. This means it’s designed to stop burning within 10 seconds after being ignited, with no flaming drips allowed. These boards are crucial in the manufacturing of electronic devices, offering durability, temperature control, and the ability to withstand harsh environments. Their application ranges from simple electronic devices to complex machinery, making them a fundamental component in the electronics industry.

What is a 94v0 Circuit Board?

In the realm of electronics, the term ’94v0′ might sound technical and intimidating. However, once you break it down, it’s quite straightforward. The ’94v0′ in a 94v0 circuit board refers to a flammability standard set by Underwriters Laboratories (UL), a global safety certification company. This standard, known as the UL 94V-0 Flammability Standard, is a measure of how a material responds to fire or ignition sources.

| Flammability Rating | Burn Time | Flaming Drips Allowed? |

|---|---|---|

| 94V-0 | <10s | No |

| 94V-1 | <30s | Yes |

| 94V-2 | <60s | Yes |

When a circuit board is labeled as ’94v0′, it means that the board’s materials have undergone and passed the UL 94V-0 flammability test. In this test, the material is ignited, and its burning characteristics are observed. A 94v0 rating indicates that the material will cease to burn within 10 seconds after being ignited, with no flaming drips allowed. This makes 94v0 circuit boards highly desirable in electronic manufacturing, as they add an extra layer of safety against potential fire hazards.

But a 94v0 circuit board isn’t just about fire safety. It’s a complex piece of technology that forms the backbone of many electronic devices. These boards are designed to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate. They are robust, reliable, and designed to function efficiently in various conditions, making them a vital component in the electronics industry.

Comparing 94v0 with Other Flammability Standards

| Flammability Rating | Burn Time | Flaming Drips Allowed? |

|---|---|---|

| HB | Slow burning; burning rate < 76 mm/min for thickness < 3 mm or burning stops before 100 mm | Yes |

| V-2 | Burning stops within 30 seconds | Yes |

| V-1 | Burning stops within 30 seconds | Drips of particles allowed as long as they are not inflamed |

| 94V-0 | Burning stops within 10 seconds | Drips of particles allowed as long as they are not inflamed |

| 5VB | Burning stops within 60 seconds | No; plaque specimens may develop a hole |

| 5VA | Burning stops within 60 seconds | No; plaque specimens may not develop a hole |

While the 94v0 rating is a highly desirable standard for circuit boards, it’s not the only flammability standard out there. Other ratings under the UL 94 standard include HB, V-1, V-2, 5VA, and 5VB. Each of these ratings represents a different level of flammability, and understanding these differences can help you make more informed decisions when it comes to choosing materials for your electronic devices.

- HB (Horizontal Burn): Materials with an HB rating burn slowly and are less flame retardant than those with a V rating. These materials are tested in a horizontal position, and to pass, they must not burn at a rate greater than a specified speed or cease burning before reaching a marked point.

- V-1, V-2 (Vertical Burn): These materials are tested in a vertical position. V-1 and V-2 materials must stop burning within a certain time after the ignition source is removed, with V-1 materials being slightly more flame retardant than V-2. Both these materials may drip flaming particles while burning.

- 5VA, 5VB (Vertical Burn with Impact): These materials are subjected to both a flame test and an impact test. 5VA materials are more flame retardant than 5VB materials and do not allow flaming drips. Both these materials, however, may develop a hole due to burning.

The 94v0 rating is the most stringent of these standards. Materials with this rating stop burning within 10 seconds and do not drip flaming particles, providing a high level of fire safety. This makes 94v0 circuit boards an excellent choice for electronic devices, especially those that need to operate in harsh or high-temperature environments.

By understanding these different flammability standards, you can better appreciate the superior fire safety provided by 94v0 circuit boards and why they are a preferred choice in the electronics industry.

Why is the 94v0 Circuit Board Important?

In the intricate world of electronics, the 94v0 circuit board holds a position of paramount importance. But what makes it so indispensable, especially for our readers who are likely to be involved in the electronics industry or simply tech enthusiasts? Let’s delve into the key reasons.

Firstly, the 94v0 circuit board is synonymous with safety. The ’94v0′ rating signifies that the material of the board will cease to burn within 10 seconds after being ignited, with no flaming drips allowed. This is a critical feature in electronic devices, which often generate heat and are sometimes used in high-temperature environments. By incorporating a 94v0 circuit board, the risk of fire is significantly reduced, providing an extra layer of safety for users.

Secondly, 94v0 circuit boards are designed for durability and reliability. These boards are built to withstand harsh environments and varying temperatures, making them ideal for a wide range of applications, from everyday consumer electronics to industrial machinery. The robust nature of 94v0 circuit boards ensures that the devices they’re used in can stand the test of time, offering long-term reliability and performance.

Lastly, the 94v0 circuit board plays a crucial role in the functionality of electronic devices. These boards are the backbone of many devices, providing the necessary mechanical support and electrical connections for various components. With a reliable circuit board like the 94v0, the functionality and performance of these devices are enhanced, leading to a better user experience.

In conclusion, the 94v0 circuit board is more than just a piece of technology. It’s a vital component that ensures the safety, reliability, and functionality of countless electronic devices. Understanding the importance of the 94v0 circuit board can help you appreciate the complex world of electronics a little more, whether you’re involved in the electronics industry or simply interested in the inner workings of your devices.

Applications of the 94v0 Circuit Board

The 94v0 circuit board, with its high safety standards and robust performance, is a cornerstone in a multitude of applications. While it’s common knowledge that these boards are used in everyday electronics and industrial machinery, let’s delve into some unique and perhaps unexpected applications of the 94v0 circuit board.

- Smart Home Systems

In the era of the Internet of Things (IoT), smart home systems are becoming increasingly prevalent. From smart thermostats to home security systems, 94v0 circuit boards are at the heart of these devices. Their durability and reliability ensure these systems can operate efficiently, providing a seamless and convenient user experience.

- Wearable Technology

Wearable technology, such as fitness trackers and smartwatches, is another interesting application of 94v0 circuit boards. These devices require compact, reliable, and safe components, making the 94v0 circuit board an ideal choice.

- Interactive Entertainment Systems

Interactive entertainment systems, such as gaming consoles and virtual reality (VR) devices, also utilize 94v0 circuit boards. These boards ensure these complex machines can operate reliably and efficiently, providing users with immersive and uninterrupted entertainment experiences.

- Eco-Friendly Appliances

As the world becomes more conscious of sustainability, eco-friendly appliances are on the rise. These appliances, such as energy-efficient air conditioners and refrigerators, rely on 94v0 circuit boards for their operation. The boards’ high safety standards and reliable performance ensure the smooth operation of these environmentally friendly devices.

In conclusion, the 94v0 circuit board finds its application in a wide range of industries, some of which may surprise you. Its importance cannot be overstated, and understanding its unique applications can provide valuable insights into the vast world of electronics.

Types of PCBs: Single-Sided and Double-Sided

Printed Circuit Boards (PCBs), including the 94v0 circuit boards, come in various types, each with its unique features and applications. Among these, single-sided and double-sided PCBs are the most common. Let’s delve into what these terms mean, how they differ, and when you might choose one over the other.

Single-Sided PCBs

As the name suggests, single-sided PCBs have their components and conductive material on one side of the board. These PCBs are the simplest and most basic type, making them a cost-effective choice for simple electronic devices. They are typically used in devices where complexity and density are not an issue, such as power supplies and printers. If you’re designing a simple device or working with a tight budget, single-sided PCBs might be the way to go.

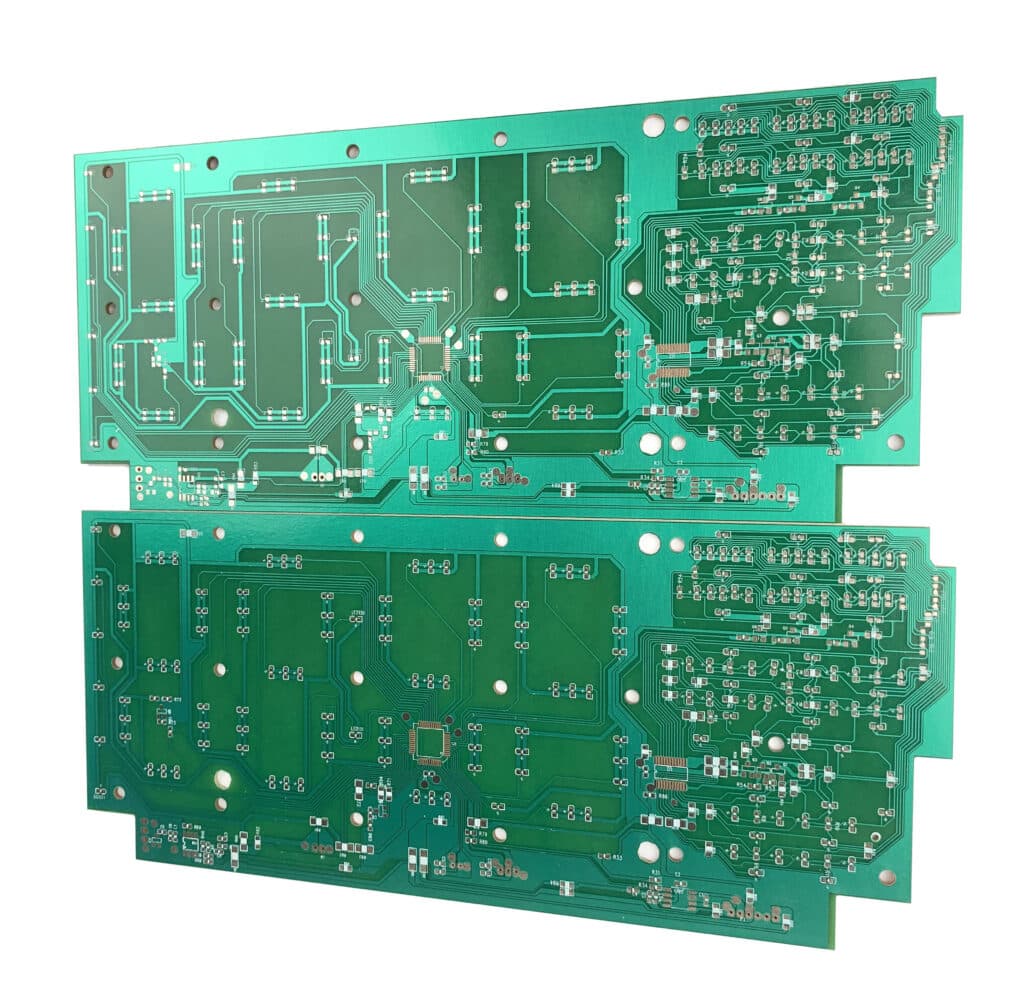

Double-Sided PCBs

Double-sided PCBs, on the other hand, have components and conductive material on both sides of the board. This allows for a higher density of components, making these boards suitable for more complex devices. Double-sided PCBs require more sophisticated manufacturing processes than single-sided ones, but they offer more flexibility in terms of design and functionality. They are commonly used in complex devices such as mobile phones and automotive controls. If your device requires a high density of components or if space is a concern, double-sided PCBs would be a better choice.

Single-Sided vs Double-Sided PCBs: Environmental Considerations

In terms of environmental impact, both types of PCBs need to be disposed of properly to prevent harm to the environment. However, double-sided PCBs, due to their complexity, may require more resources to manufacture and recycle than single-sided PCBs. As sustainability becomes more important, these considerations could influence the choice of PCBs in future electronic designs.

In conclusion, both single-sided and double-sided PCBs have their unique advantages, applications, and environmental impacts. Understanding these differences can help you make informed decisions when it comes to choosing the right type of PCB for your specific needs and sustainability goals.

Ensuring Quality and Reliability in PCB Manufacturing

Quality and reliability are two critical factors in PCB manufacturing. They determine the performance, safety, and longevity of the electronic devices in which the PCBs are used. Here, we’ll explore some key aspects that contribute to ensuring quality and reliability in PCB manufacturing, particularly when using 94v0 materials.

Design and Layout

The design and layout of a PCB significantly impact its performance. A well-designed PCB ensures efficient electrical connections and reduces the risk of short circuits. It also takes into account the heat generated by the device and provides for adequate heat dissipation. When using 94v0 materials, special attention should be paid to the layout to maximize the material’s flame-retardant properties.

Manufacturing Process

The manufacturing process needs to be precise and controlled to ensure the quality of the PCB. This includes accurate etching of the copper layers, precise drilling of holes, and careful soldering of components. Any errors in these processes can lead to faults in the PCB, affecting its performance and reliability. When working with 94v0 materials, the manufacturing process should also ensure that the flame-retardant properties of the material are not compromised.

94V0 and Environmental Protection and Human Health

When it comes to the intersection of 94V0 circuit boards and environmental protection, it’s crucial to understand the role of flame retardants. Flame retardants are substances that are added to materials, including the 94V0 PCBs, to prevent the spread of fire. They are essential in ensuring the safety of electronic devices, but their impact on the environment and human health is a topic of ongoing research and discussion.

Flame Retardants and the Environment

Flame retardants, particularly halogenated ones, have been associated with a variety of environmental issues. They can persist in the environment, accumulate in living organisms, and potentially cause harm to wildlife. However, the 94V0 PCBs use a specific type of flame retardant known as tetrabromobisphenol A (TBBPA). According to a report by the US Environmental Protection Agency (EPA), TBBPA has a moderate potential for bioaccumulation and its primary hazard is aquatic toxicity.

Flame Retardants and Human Health

The impact of 94V0 material on human health largely depends on the specific flame retardant used in the PCB. The EPA report states that human health hazard designations for TBBPA, the most commonly used flame retardant in FR-4 PCBs, are low to moderate. Moderate designations were determined for carcinogenicity, developmental toxicity, and eye irritation. However, it’s important to note that the level of available human health and environmental information varies widely by flame-retardant chemical. Little information exists concerning many of the alternative flame-retardant materials included in this report.

Conclusion

In conclusion, while the 94V0 material itself may not directly impact human health, the specific flame retardants used in the PCBs can have varying degrees of impact on human health and the environment. The impact can range from low to moderate based on the specific flame retardant used, and further studies are needed to fully understand the potential impacts of these materials. As a responsible PCB manufacturer, we at Rowsum are committed to staying informed about these issues and implementing the best practices to minimize any potential harm.

Conclusion

In this article, we’ve explored the 94v0 circuit board, its importance, applications, types, and the role it plays in ensuring quality and reliability in PCB manufacturing. We’ve also delved into the environmental and health impacts of the 94v0 material and the flame retardants used in it.

Choosing the right PCB material is not just about device performance; it’s also about environmental responsibility and human health. As a PCB manufacturer, Rowsum is committed to staying informed about these issues and implementing best practices to minimize any potential harm.

For more insights into the world of PCB manufacturing, we invite you to explore our other blog posts:

- Understanding the PCB Manufacturing Process

- The Future of PCBs: Trends to Watch

- PCB Design: Best Practices for Beginners

FAQs

1. What is a 94v0 circuit board?

A 94v0 circuit board refers to a PCB that has passed the UL 94V-0 flammability test. This means that the board self-extinguishes within 10 seconds after being set on fire, with no flaming drips.

2. Why is the 94v0 circuit board important?

The 94v0 circuit board is important because of its flame-retardant properties. It’s used in various applications where fire safety is a concern, such as in consumer electronics, automotive electronics, and aerospace applications.

3. What are the applications of the 94v0 circuit board?

The 94v0 circuit board is used in a wide range of applications, including consumer electronics, automotive electronics, aerospace applications, and more. Its flame-retardant properties make it suitable for use in any device where fire safety is a concern.

4. What is the difference between single-sided and double-sided PCBs?

Single-sided PCBs have components and conductive material on one side of the board, while double-sided PCBs have components and conductive material on both sides. Double-sided PCBs allow for a higher density of components and are suitable for more complex devices.

5. What is the impact of 94v0 material on the environment and human health?

The impact of 94v0 material on the environment and human health largely depends on the specific flame retardant used in the PCB. The most commonly used flame retardant, TBBPA, has a moderate potential for bioaccumulation and its primary hazard is aquatic toxicity. The human health hazard designations for TBBPA are low to moderate. Further studies are needed to fully understand the potential impacts of these materials.