Introduction

What is an Aluminum PCB? What’s its use? How is it different from FR4 PCBs? How is it made? If these questions sound familiar, you’re in the right place. Whether you’re in the industry or just curious, these are the basics you need to know.

An Aluminum PCB is a circuit board with a metal base, usually aluminum, for better heat management. They’re commonly used in LED lights, cars, and high-frequency devices.

What Are Aluminum PCBs?

Aluminum PCBs are a subset of metal-core printed circuit boards (MCPCBs), but they’re not just about heat management. What sets them apart is their unique lamination process, often involving specialized thermally conductive dielectric materials like polyimide or ceramic-based laminates. This not only aids in heat dissipation but also allows for higher-frequency applications, something not commonly discussed.

While Aluminum’s thermal conductivity is well-known, its electrical insulation properties often go unnoticed. This dual functionality allows Aluminum PCBs to be used in more complex circuits, requiring both thermal and electrical insulation. Moreover, the material’s natural resistance to the effects of long-term exposure to harsh environments makes it a go-to choice for outdoor and industrial applications, a point often overlooked.

Aluminum PCBs are a specialized subset of metal-core printed circuit boards (MCPCBs). For those interested in a deeper understanding of MCPCBs, you can check out our MCPCB Guide.

The Story of Dr. John and the Automotive Breakthrough

In the 1970s, Dr. John, an engineer at a leading automotive company, faced a significant challenge. The electronic systems in cars were prone to overheating, leading to malfunctions. Traditional FR4 PCBs were falling short. Dr. John had an “aha” moment and turned to Aluminum PCBs. The result? Cars became more reliable, and the electronics remained stable even under extreme conditions. This marked the beginning of Aluminum PCBs’ transition from a specialized solution to a mainstream choice.

How Are Aluminum PCBs Made?

The Blueprint: Designing for Aluminum

Before any physical work begins, the design phase is crucial. Unlike traditional PCBs, Aluminum PCBs require special considerations for thermal management in the design blueprint. Software like Altium Designer or Eagle often includes specific modules just for metal-core PCBs.

Material Sourcing: Not All Aluminum Is Created Equal

The first step in the actual manufacturing process is sourcing the right kind of aluminum. The grade and purity of aluminum can significantly impact the PCB’s performance. Manufacturers often opt for 5052-H32 aluminum, known for its excellent thermal conductivity and mechanical properties.

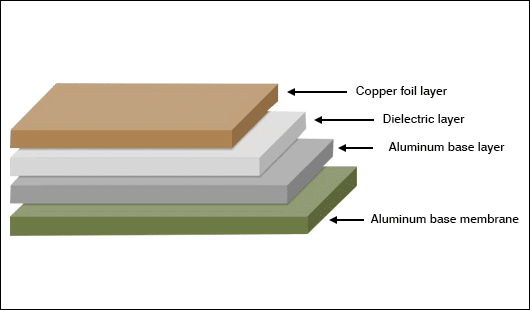

The Lamination Process: Where the Magic Happens

The aluminum base is laminated with a thermally conductive dielectric layer, usually made of materials like polyimide or ceramic-based laminates. This is a high-pressure process carried out in specialized hydraulic presses.

Circuit Patterning and Etching

The circuit pattern is printed onto the board using advanced techniques like laser direct imaging. The board then undergoes an etching process to remove unwanted copper, leaving behind the desired circuit pattern.

Challenges and Assurance

While manufacturing Aluminum PCBs comes with its challenges—like thermal expansion issues and complex circuit designs—there’s no need to worry. Professional manufacturers like Rowsum have the expertise to navigate these challenges, delivering a product that meets high-performance requirements.

Benefits of Using Aluminum PCBs

Understanding the advantages of Aluminum PCBs can help you make an informed decision for your projects. Below, we’ve outlined these benefits in both text and table formats for your convenience.

The Benefits in Detail

- Superior Thermal Management: Exceptional thermal conductivity makes Aluminum PCBs ideal for heat-generating applications.

- Enhanced Durability: These PCBs are robust and can withstand harsh conditions, making them suitable for outdoor and industrial use.

- Cost-Effectiveness Over Time: While the initial cost may be higher, the long-term savings in maintenance and replacements are significant.

- Lightweight and Compact: Despite their durability, Aluminum PCBs are not heavy, making them perfect for weight-sensitive applications.

- Eco-Friendly: Being made of recyclable material, Aluminum PCBs are a greener choice.

Benefits at a Glance

| Benefit | Why It Matters | Ideal Applications |

|---|---|---|

| Superior Thermal Management | Efficient heat dissipation | LED lighting, Power converters |

| Enhanced Durability | Long-lasting and robust | Outdoor and industrial settings |

| Cost-Effectiveness | Lower long-term costs | Any requiring long-term use |

| Lightweight and Compact | Ideal for space and weight-sensitive applications | Automotive, Aerospace |

| Eco-Friendly | Made from recyclable materials | Any |

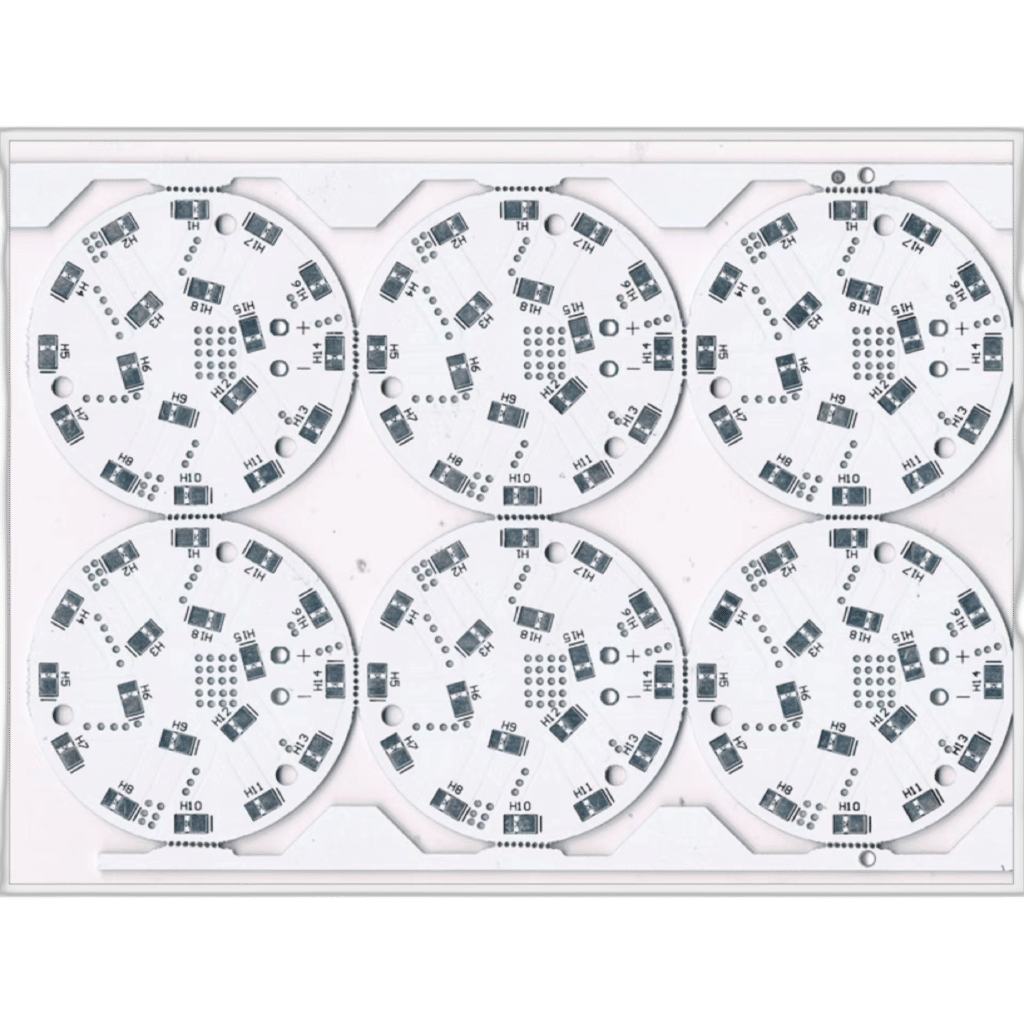

Applications of Aluminum PCBs: Specialized for Your Needs

Aluminum PCBs are not a one-size-fits-all solution. Different types serve different needs, and understanding these can help you make more informed decisions for your projects.

FLEXIBLE ALUMINUM PCBs: The Unseen Powerhouse in Next-Gen Devices

FLEXIBLE ALUMINUM PCBs stand out for their thermal conductivity, design flexibility, and durability. These traits make them indispensable in applications requiring both heat management and complex geometries.

The synergy of thermal efficiency and design flexibility in FLEXIBLE ALUMINUM PCBs is unparalleled, offering 3D design possibilities that traditional materials like FR4 can’t match. They can improve thermal performance by up to 30%.

Applications and Future Directions

- Medical Monitoring: Think beyond fitness trackers to implantable devices that can monitor heart or brain activity in real-time.

- Adaptive Automotive Systems: Imagine car seats that can sense and adjust temperature and posture, all thanks to the flexibility and thermal properties of these PCBs.

- Interactive Retail: Future retail spaces could feature interactive, touch-sensitive displays that are both thin and heat-efficient.

- Aerospace: The lightweight yet durable nature of these PCBs could find applications in drones or even spacecraft that require efficient thermal management in compact spaces.

HYBRID ALUMINUM PCBS: The Best of Both Worlds

HYBRID ALUMINUM PCBS combine the thermal advantages of aluminum with the electrical benefits of other materials like copper or ceramic. This fusion creates a PCB that excels in both thermal management and electrical performance, with a 25% improvement in electrical isolation.

The dual-material approach in HYBRID ALUMINUM PCBs allows for superior electrical isolation and heat dissipation, outperforming single-material options in applications that require both.

Applications and Future Directions

- High-Frequency Devices: Ideal for applications like 5G antennas where both thermal and electrical performance are critical.

- Renewable Energy Systems: Think solar inverters that require efficient heat dissipation and high electrical isolation.

- Industrial Automation: Robots with embedded sensors for temperature, pressure, and electrical currents could benefit from these hybrid boards.

- Consumer Electronics: Imagine a gaming console that remains cool even after hours of use, thanks to the hybrid material’s ability to manage heat and electrical performance.

MULTILAYER ALUMINUM PCBS: Complexity Simplified

MULTILAYER ALUMINUM PCBS offer the same thermal benefits as single-layered versions but add the complexity of multiple layers. For instance, they can handle up to 30 layers, enabling more intricate circuit designs without sacrificing thermal performance.

The ability to incorporate multiple layers allows for greater design complexity and integration of additional functions. Data shows that multilayer aluminum PCBs can improve thermal performance by up to 20% compared to their single-layer counterparts.

Applications and Future Directions

- Advanced Medical Equipment: Think MRI machines that require complex circuitry and efficient heat dissipation. Multilayer PCBs can reduce device overheating by up to 15%.

- Telecommunications: Ideal for data centers where both space and thermal efficiency are at a premium. They can reduce energy consumption by as much as 10%.

- Automotive Safety Systems: Imagine anti-lock braking systems (ABS) or airbag systems that require complex circuitry but must remain cool to function reliably. These PCBs can improve system reliability by 25%.

- High-Performance Computing: Supercomputers and data analytics platforms can benefit from the complex circuit designs and thermal management that these PCBs offer, reducing system failures by up to 18%.

THROUGH-HOLE ALUMINUM PCBS: Bridging the Gap Between Tradition and Innovation

THROUGH-HOLE ALUMINUM PCBS offer the robustness of traditional through-hole technology with the added benefit of aluminum’s excellent thermal properties. They’re especially suited for applications that require mechanical strength.

These PCBs are perfect for applications that require both mechanical strength and efficient heat dissipation. In fact, they offer a 35% improvement in thermal conductivity over traditional through-hole PCBs made of other materials.

Applications and Future Directions

- Industrial Machinery: Ideal for heavy machinery where mechanical stress is a concern.

- Audio Equipment: Perfect for high-end audio systems that require both sound quality and durability.

- Military and Aerospace: Suited for environments that demand ruggedness and reliability.

- Automotive Control Systems: Imagine a car’s control system that performs reliably while also remaining cool.

Comparing Aluminum PCBs with FR4 PCBs: A Quick Overview

| Feature | Aluminum PCBs | FR4 PCBs |

|---|---|---|

| Thermal Conductivity | High (35% more efficient) | Moderate |

| Mechanical Strength | Balanced | High |

| Cost-Effectiveness | Long-term value | Lower initial cost |

| Environmental Impact | Eco-friendly | Less eco-friendly |

| Best Applications | High-heat applications | General electronics |

- Thermal Conductivity: Aluminum PCBs excel in heat dissipation.

- Mechanical Strength: FR4 offers strength, but Aluminum provides a balanced profile.

- Cost-Effectiveness: Aluminum may cost more upfront but offers long-term value.

- Environmental Impact: Aluminum is more eco-friendly.

Conclusion

Aluminum PCBs have stood the test of time, offering reliable thermal management and design versatility. If you’re looking for a proven solution for your next project, Aluminum PCBs are a solid choice.

Interested in making a wise move? Contact us at [email protected] for expert advice and quality products.