Our Services

One-Stop Components Sourcing Solution for Your Manufacturing Needs

Discover Rowsum’s Components Sourcing expertise, your one-stop solution for all electronic component needs. We’re dedicated to offering top-quality components at competitive prices, ensuring a hassle-free experience.

What's the benefits

- Global sourcing strategies

- Access to obsolete and hard-to-find components

- Alternative component solutions

- Rigorous quality control and testing

- Local staff in the US and Europe for better support

- Fast and reliable delivery with US warehouse

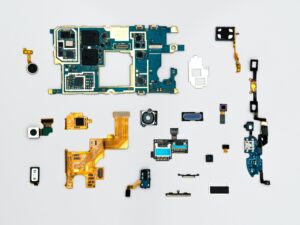

Electronic Components Hub for PCBA Buyers

Introduction to Components Sourcing

Welcome to Rowsum Electronics’ Components Sourcing services! We know that finding the right components is crucial for producing high-quality PCBAs, and our team is dedicated to making that process as seamless as possible for you. Our comprehensive sourcing solutions are designed to save you time, reduce costs, and ensure the optimal performance of your products.

With our extensive industry experience and strong supplier network, we source a wide range of components that meet the highest quality standards. Whether you’re looking for common components or those that are difficult to find, Rowsum is here to help you every step of the way. We take pride in our commitment to providing exceptional customer service, ensuring that your needs are met and your projects run smoothly.

Let Rowsum be your trusted partner in navigating the complexities of components sourcing, and experience the difference our expertise and dedication can make for your PCBA projects.

Our Sourcing Strategy and Supply Chain Partners

Comprehensive Sourcing Strategy and Trusted Supply Chain Partnerships: Leveraging Local Presence in the US and Europe

At Rowsum Electronics, our sourcing strategy is centered on providing the best value and quality for our clients while maintaining efficient and reliable procurement processes. We have established a comprehensive approach to components sourcing that encompasses several key aspects:

1. Global Supply Chain Network with Local Presence: Our extensive network of trusted suppliers and partners spans across the globe, including a strong local presence in the US and Europe. This ensures access to a vast selection of components to meet your project requirements while benefiting from localized expertise and support.

2. Strategic Partnerships: We forge long-lasting relationships with our suppliers, leveraging our buying power to negotiate the best possible pricing and terms for our clients.

3. Quality Assurance: Our team conducts rigorous quality control checks on all sourced components, ensuring they meet our high standards of quality and reliability before being utilized in your projects.

4. Cost Optimization: We constantly analyze market trends and pricing data to identify opportunities for cost savings and pass those benefits on to our clients.

5. Supply Chain Risk Management: We proactively monitor the supply chain to identify and mitigate any potential risks that could impact component availability or project timelines.

In addition to our well-rounded sourcing strategy, we also maintain strong relationships with our supply chain partners. These trusted partners include:

– uthorized Distributors: We work with authorized distributors to ensure genuine, high-quality components from reliable sources.

– Original Component Manufacturers (OCMs): Our partnerships with OCMs allow us to access components directly from the manufacturers, ensuring quality and authenticity.

– Independent Distributors: We collaborate with a select group of independent distributors who can provide hard-to-find or obsolete components, broadening our sourcing capabilities.

With our robust sourcing strategy and the advantage of having a local presence in the US and Europe, Rowsum Electronics is committed to delivering exceptional components and service for all your PCBA need

Cost-effective and Quality Components: Striking the Perfect Balance for Your PCBA Projects

At Rowsum Electronics, we understand the importance of delivering cost-effective and quality components for your PCBA projects. Our sourcing team is dedicated to finding the perfect balance between cost and quality, ensuring you receive exceptional value without compromising on performance or reliability. Here’s how we achieve this:

1. Strategic Procurement:

Our experienced procurement team leverages its expertise and market insights to negotiate the best possible prices for components without sacrificing quality. This enables us to provide cost-effective solutions that meet your budgetary requirements while maintaining high standards of performance.

2. Rigorous Quality Control:

We enforce strict quality control processes for all sourced components. Our team inspects and tests each component to verify its quality, authenticity, and compliance with industry standards. This ensures that only top-notch components are used in your projects.

3. Volume Discounts:

By consolidating our purchasing power, we secure volume discounts from our suppliers, which allows us to pass on cost savings to our clients.

4. Alternative Component Sourcing:

In cases where certain components are either obsolete or have high price tags, our engineering team can help identify high-quality alternatives that provide similar functionality while offering cost savings.

5. Continuous Improvement:

We constantly strive to enhance our sourcing processes and stay updated on the latest industry trends, ensuring we can provide the most cost-effective and quality components for your PCBA projects.

At Rowsum Electronics, our commitment to delivering cost-effective and quality components is unwavering. We understand that the perfect balance between cost and quality is crucial for the success of your PCBA projects, and we are dedicated to providing you with the best possible solutions to meet your needs.

Obsolete and Hard-to-find Components: Comprehensive Solutions to Tackle Your PCBA Challenges

At Rowsum Electronics, we are committed to helping you overcome the challenges of sourcing obsolete and hard-to-find components for your PCBA projects. Our comprehensive approach ensures that you receive the best possible solutions tailored to your unique needs. Here’s how we address the obstacles associated with sourcing obsolete and hard-to-find components:

1. Component Lifecycle Monitoring:

We continuously monitor the lifecycle of components used in your design to identify potential obsolescence risks and provide timely updates on the availability of required components. This proactive approach enables you to make informed decisions and avoid potential issues.

2. Collaborative Component Sourcing:

Working closely with our network of trusted suppliers and partners, we source obsolete and hard-to-find components through multiple channels, ensuring that we obtain the best possible pricing and lead times for your project.

3. In-depth Component Verification:

Our team conducts rigorous verification of all sourced components, including visual inspection, X-ray analysis, and electrical testing, to ensure their quality, authenticity, and compliance with industry standards.

4. Cross-Referencing and Alternate Component Recommendations:

Leveraging extensive cross-referencing databases, we identify equivalent or alternate components that can provide similar performance and maintain the functionality of your designs. We also provide detailed comparisons and recommendations to support your decision-making process.

5. Obsolescence Management and Planning:

Our obsolescence management services help you develop a robust plan to mitigate the impact of component obsolescence on your projects. This includes risk assessment, proactive communication with suppliers, and establishing a long-term component procurement strategy.

6. Custom Component Engineering:

In cases where suitable alternatives are not available, our experienced engineering team can design custom components to meet your project’s specific requirements, ensuring seamless integration with your existing designs.

At Rowsum Electronics, we understand the unique challenges posed by sourcing obsolete and hard-to-find components, and we are determined to provide comprehensive solutions to overcome these obstacles and ensure the success of your PCBA projects.

Alternative Component Solutions

Rowsum Electronics understands that finding the perfect components for your PCBA projects is not always straightforward. Component shortages, price fluctuations, and discontinued parts can make the sourcing process challenging. Our alternative component solutions aim to minimize disruptions, optimize your designs, and maintain high-quality standards.

1. Comprehensive Component Analysis:

Our experienced engineering team analyzes your design requirements and identifies alternative components that offer similar or better performance. By considering factors such as availability, cost, and compliance, we ensure that the recommended alternatives align with your project’s goals.

2. Cross-referencing and Compatibility Assessment:

We leverage extensive component databases and cross-referencing tools to find suitable replacements for the required components. Our team also conducts compatibility assessments to ensure that the recommended alternatives integrate seamlessly with your design, without compromising performance or functionality.

3. Cost-effective Solutions:

Our strong relationships with suppliers and partners enable us to negotiate favorable pricing and lead times for alternative components. By sourcing cost-effective solutions, we help you optimize your budget and maintain the desired level of quality.

4. Quality Assurance and Testing:

Rowsum Electronics is committed to upholding the highest quality standards. We perform rigorous quality checks on all alternative components, including visual inspections, electrical testing, and compliance verification, to ensure their reliability and performance meet or exceed your expectations.

5. Ongoing Support and Consultation:

Our support doesn’t end with the delivery of alternative component solutions. We offer ongoing consultation and assistance, addressing any concerns or queries that may arise throughout your project’s lifecycle. Our goal is to ensure that you receive exceptional service from start to finish.

At Rowsum Electronics, we are dedicated to helping you navigate the complexities of component sourcing and providing expert recommendations for alternative solutions. With our extensive industry knowledge, commitment to quality, and customer-focused approach, we are confident in our ability to support and optimize your PCBA projects.

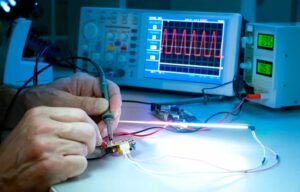

Rigorous Quality Control and Testing

At Rowsum Electronics, we firmly believe that the success of your PCBA projects relies on the quality and performance of each component. To guarantee that the components we source meet or exceed your expectations, we implement a rigorous quality control and testing process.

1. Incoming Inspection:

Upon receipt of components from suppliers, our quality control team conducts a thorough incoming inspection. This process involves visual checks for any physical defects, damage, or discrepancies, ensuring that the components meet your specified requirements.

2. Component Verification:

To verify the authenticity and performance of each component, we perform comprehensive tests and inspections, including electrical testing, X-ray inspections, and decapsulation analysis. This ensures that all components are genuine and function as intended.

3. Compliance Verification:

Rowsum Electronics is committed to upholding industry standards and regulations. We verify that all sourced components comply with relevant standards, such as RoHS, REACH, and UL. This ensures that the components we provide are safe, reliable, and environmentally friendly.

4. In-process Quality Control:

During the PCBA assembly process, our quality control team closely monitors the production line, conducting real-time inspections and implementing corrective actions whenever necessary. This proactive approach minimizes the risk of defects and ensures that your PCBA projects are completed to the highest standards.

5. Final Testing and Inspection:

Before shipping your completed PCBA projects, we perform a final round of testing and inspection. This includes functional testing, in-circuit testing (ICT), automated optical inspection (AOI), and X-ray inspection, which further validates the performance, functionality, and quality of your assembled boards.

At Rowsum Electronics, we are dedicated to providing components that meet the most stringent quality requirements. Our rigorous quality control and testing process, combined with our commitment to customer satisfaction, ensure that your PCBA projects are built with the highest level of precision and reliability.

Warehouse Management and Quality Control

At Rowsum Electronics, we are committed to providing top-quality components and exceptional customer service. Our warehouse management and quality control processes play a vital role in ensuring the efficiency and reliability of our component sourcing and PCBA production.

1. Organized Warehouse Management:

We maintain well-organized warehouse systems in both China and the United States, allowing us to store and manage components efficiently. Our team uses advanced inventory management software to track stock levels, monitor expiration dates, and prevent stock discrepancies. This enables us to quickly locate and retrieve components when needed, reducing lead times and ensuring a smooth production process.

2. Global Storage Facilities:

Our strategic decision to rent a warehouse in the United States demonstrates our commitment to better serve our global clientele. This additional warehouse enables us to shorten delivery times, reduce shipping costs, and provide localized support to our customers in the United States and surrounding regions.

3. Environmental Control:

Our warehouses are designed with environmental control in mind, ensuring optimal conditions for component storage. We maintain clean, temperature-controlled environments with proper humidity levels, safeguarding the integrity of components and preventing potential damage.

4. Rigorous Quality Control (QC):

We adhere to strict quality control procedures to ensure that every component we source meets or exceeds industry standards. Our QC team inspects components upon arrival, checking for any discrepancies, damage, or counterfeit parts. We also conduct regular spot checks and audits, guaranteeing the ongoing quality and reliability of our inventory.

5. Continuous Improvement:

At Rowsum Electronics, we are dedicated to continuous improvement in all aspects of our operations. We regularly review and update our warehouse management and quality control processes to incorporate best practices, new technologies, and feedback from our customers. This commitment to excellence enables us to provide you with the best possible service and support for your PCBA projects.

By implementing organized warehouse management, strategic global storage facilities, and rigorous quality control procedures, Rowsum Electronics ensures the efficiency and reliability of our component sourcing and PCBA production. Our dedication to excellence and continuous improvement allows us to deliver top-quality components and exceptional customer service, supporting your PCBA projects every step of the wa

Delivery and Lead Time

At Rowsum Electronics, we understand the importance of timely component sourcing and delivery for your PCBA projects. Our efficient supply chain management and global network enable us to provide you with the components you need when you need them, minimizing delays and ensuring a seamless production process.

1. Streamlined Supply Chain Management:

We have developed strong relationships with reliable suppliers and manufacturers worldwide, allowing us to source components quickly and efficiently. Our team constantly monitors market trends and component availability, enabling us to identify potential supply chain issues and make adjustments as needed.

2. Global Network:

With our global network, including warehouse facilities in China and the United States, as well as our dedicated business managers in the United States and Europe, we are well-positioned to serve our customers worldwide. Our extensive network allows us to shorten lead times and deliver components to your facility promptly, wherever you are located.

3. Accurate Lead Time Estimates:

We provide accurate lead time estimates for every order, ensuring that you have a clear understanding of when your components will arrive. Our team works closely with our suppliers and transportation partners to coordinate shipping schedules and prevent delays, keeping you informed every step of the way.

4. Expedited Shipping Options:

For urgent orders or tight project deadlines, we offer expedited shipping options to get your components to you as quickly as possible. Our team will work with you to determine the best shipping solution for your needs, ensuring that your project stays on track.

5. Tracking and Support:

Once your order is shipped, we provide tracking information, allowing you to monitor the progress of your shipment. Our customer support team is always available to answer any questions or address any concerns you may have regarding your order and delivery.

At Rowsum Electronics, we are committed to providing efficient and timely component sourcing and delivery for your PCBA projects. Our streamlined supply chain management, global network, and dedicated customer support ensure that you receive the components you need, when you need them, helping you bring your projects to completion on time and within budget.

Frequently Asked Questions (FAQs) on Components Sourcing

1. Can you source components from specific manufacturers or suppliers?

Yes, we can source components from your preferred manufacturers or suppliers. Please provide us with the relevant information, and we will do our best to accommodate your request.

2. How do you ensure the quality of the components you source?

We work with reliable and trusted suppliers, and we perform rigorous quality control checks on all components we receive. Our experienced team of engineers and quality control staff ensure that every component meets our high standards before it is used in your PCBA project.

3. What if I need an obsolete or hard-to-find component?

Our extensive network and relationships with suppliers enable us to locate and source obsolete and hard-to-find components. If a specific component is no longer available, our engineering team can also help you identify suitable alternative components.4. Can you provide alternative component solutions?

Yes, our engineering team can work with you to identify alternative components that meet your specifications and requirements. We aim to provide cost-effective and high-quality solutions to keep your project on track.5. What is your standard lead time for components sourcing?

Our standard lead time varies depending on the components and quantities required. We will provide an accurate lead time estimate when you place your order, and we work diligently to ensure that components are sourced and delivered within the specified timeframe.6. Can you expedite component sourcing and delivery?

Yes, we offer expedited shipping options for urgent orders or tight project deadlines. Please let us know your requirements, and we will work with you to determine the best shipping solution for your needs.7. How can I track my order?

Once your order is shipped, we will provide you with tracking information, allowing you to monitor the progress of your shipment. Our customer support team is also available to answer any questions or address any concerns you may have regarding your order and delivery.If you have any additional questions about our components sourcing services, please feel free to contact our customer support team. We’re here to help and ensure your PCBA project is a success.

Reliable Components Sourcing Partner for Your Business Success

Thank you for considering Rowsum as your Components Sourcing partner. We are committed to providing you with the best quality components at the most competitive prices. Our team of experts will work closely with you to ensure that your requirements are met and that your project is a success.