Introduction

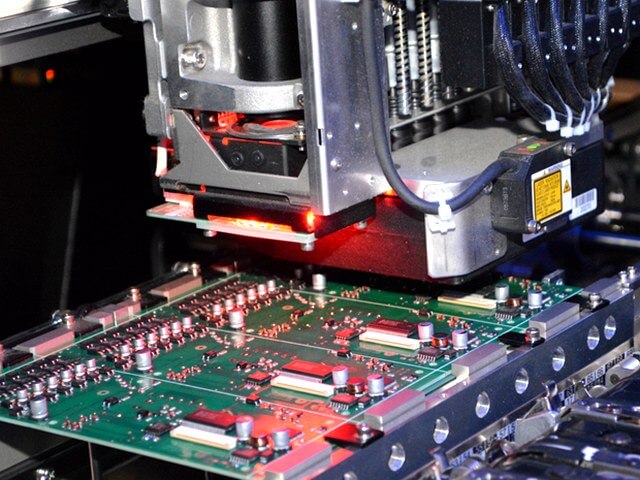

Have you ever wondered how the electronic devices you use daily are made? How does your smartphone, with its complex array of features and functions, come to life from a mere concept? What about the intricate systems that power your car, or the high-tech devices that make modern healthcare possible? Behind all these innovations lies a critical process that often goes unnoticed: Electronics Manufacturing Services (EMS).

Electronics Manufacturing Services (EMS) play a pivotal role in bringing electronic products to life. They are the backbone of the electronics industry, providing comprehensive services that transform a design into a fully functional and market-ready product. From the circuit boards in your computer to the advanced systems in aerospace technology, EMS is the unsung hero that makes it all possible.

In this article, we’ll delve into the world of EMS, exploring its importance, how it works, and why it’s a game-changer in the electronics industry, particularly in Printed Circuit Board (PCB) manufacturing. Whether you’re a business looking to understand EMS better or an enthusiast curious about the process behind your favorite gadgets, this comprehensive guide is for you. So, let’s dive in!

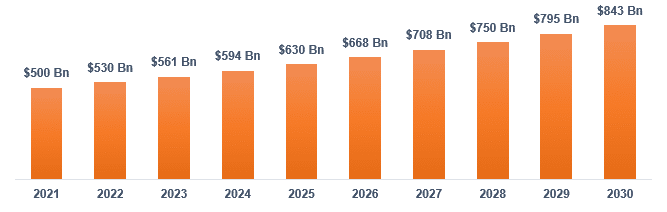

The Global EMS Market

The Electronics Manufacturing Services (EMS) market is a dynamic and rapidly growing sector. According to a recent report, the global EMS market is expected to reach USD 790 billion by 2030, growing at a Compound Annual Growth Rate (CAGR) of 6% from 2022 to 2030.

The Role of China in the Global EMS Market

China plays a significant role in this growth. As a global manufacturing hub, China is home to numerous EMS providers, including Rowsum, that offer high-quality PCB and PCBA manufacturing services. These companies leverage advanced technologies, skilled workforce, and efficient supply chains to deliver cost-effective and reliable solutions to clients worldwide.

| Region | 2018 Market Share | 2019 Market Share | 2020 Market Share | 2021 Market Share | 2022 Market Share | 2023 Estimated Market Share |

|---|---|---|---|---|---|---|

| APAC | 50.1% | 51.2% | 52.4% | 53.7% | 55.1% | 56.6% |

| Americas | 29.2% | 28.5% | 27.8% | 27.1% | 26.4% | 25.7% |

| EMEA | 20.7% | 20.3% | 19.8% | 19.2% | 18.5% | 17.7% |

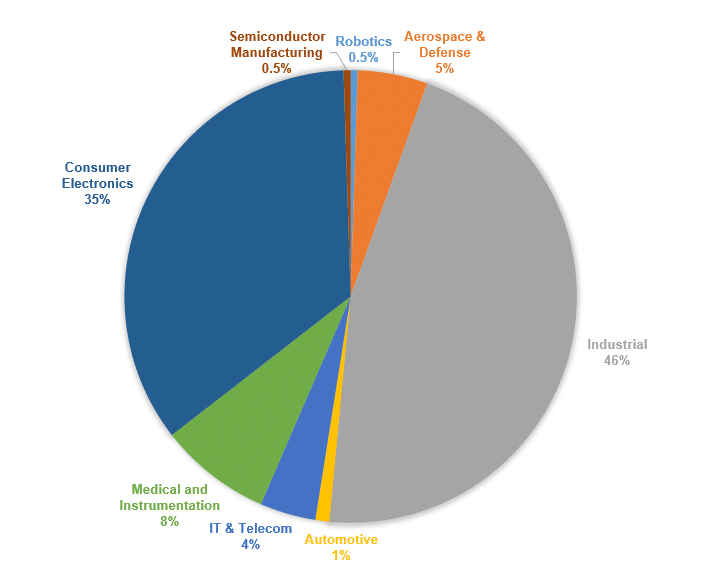

EMS Market Segmentation

The EMS market is diverse, serving various industries such as automotive, communications, computers, consumer electronics, industrial automation and IoT, and healthcare. Each of these sectors relies on EMS for the production of their electronic components and systems.

The Impact of EMS on PCB Manufacturing

In the realm of PCB manufacturing, EMS providers play a critical role. They handle the intricate process of PCB assembly, ensuring the boards meet the highest standards of quality and performance. This capability is particularly important given the increasing complexity of electronic devices and the growing demand for miniaturization and high-speed performance.

History of EMS

The history of Electronics Manufacturing Services (EMS) is a captivating tale of innovation, growth, and adaptation. It’s a story that begins in the heart of Silicon Valley and spans across the globe, mirroring the rapid evolution of the electronics industry.

- The Birth of EMS

Our story begins in 1977, in the bustling tech hub of Silicon Valley. Amidst the rise of personal computers and the burgeoning tech industry, a new player entered the scene: Solectron Corporation, the world’s first EMS company. At a time when the concept of outsourcing manufacturing was still novel, Solectron dared to venture into uncharted territory, offering manufacturing services to Original Equipment Manufacturers (OEMs).

- The Growth and Evolution of EMS

As we journey into the 1980s, a significant turning point awaits. The advent of surface mount technology (SMT) revolutionized the manufacturing process. This new technology allowed for the creation of more complex and compact electronic devices, propelling the EMS industry into a new era of growth and innovation.

- EMS and the Rise of PCB Manufacturing

Our story now takes us deeper into the world of electronics, where EMS providers began to offer more specialized services, including Printed Circuit Board (PCB) assembly. PCBs, the backbone of any electronic device, required a high level of precision and expertise to manufacture. EMS providers, with their specialized knowledge and capabilities, stepped in to fill this need, becoming an integral part of the electronics manufacturing process.

- The Modern EMS Industry

Fast forward to today, and the EMS industry has grown into a global powerhouse. From the smartphones in our pockets to the cars we drive and the medical devices that save lives, EMS providers play a crucial role in bringing these products to life. They are the unsung heroes of the electronics industry, working behind the scenes to turn ideas into reality.

Services Offered by EMS Companies

Electronics Manufacturing Services (EMS) companies offer a comprehensive suite of services that cover the entire lifecycle of an electronic product. These services go beyond mere manufacturing, providing end-to-end solutions that streamline the production process, ensuring quality, and reducing time-to-market. Let’s delve into the key services offered by EMS companies.

Design and Prototyping

The journey of an electronic product starts with an idea. EMS companies help bring this idea to life through their design and prototyping services. They work closely with the client to understand their requirements and create a design that meets these needs. This involves creating schematic diagrams, selecting components, and designing the PCB layout. Once the design is finalized, a prototype is created for testing and validation. This step is crucial in identifying any potential issues before moving on to mass production.

PCB Fabrication

At the heart of any electronic device is a Printed Circuit Board (PCB). EMS companies offer PCB fabrication services, where they manufacture the PCBs based on the design specifications. This involves multiple steps, including etching the copper layers, drilling holes for component leads, and applying solder mask and silkscreen. The result is a high-quality PCB that forms the foundation of the electronic device. The PCBs can be single-sided, double-sided, or multi-layered, depending on the complexity of the design.

PCB Assembly

Once the PCBs are fabricated, the next step is assembly. This involves mounting and soldering the electronic components onto the PCB. EMS companies offer both Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly services. SMT is used for smaller components, while THT is used for larger components or those that need to withstand physical stress. The assembly process is often automated to ensure precision and efficiency. EMS companies also offer mixed technology assembly, which involves using both SMT and THT in a single PCB, allowing for greater flexibility and complexity in the design.

Testing and Quality Assurance

Quality assurance is a critical aspect of the EMS process. EMS companies conduct rigorous testing to ensure the final product meets the required standards and specifications. This can include functional testing, where the product is tested under conditions that mimic its intended use, and reliability testing, where the product is subjected to stress conditions to test its durability and longevity. Some EMS companies also offer environmental testing, which involves testing the product under various environmental conditions to ensure it can withstand real-world use.

Supply Chain Management and Logistics

EMS companies also offer supply chain management and logistics services. They manage the procurement of components, inventory management, and delivery of the final product. This involves sourcing components from reliable suppliers, maintaining optimal inventory levels to prevent stockouts or excess inventory, and ensuring the final product is delivered to the right place at the right time. This helps OEMs streamline their operations, reduce costs, and ensure timely delivery of their products.

After-Sales Support

The role of an EMS company doesn’t end with the delivery of the product. They also provide after-sales support, which can include repair services, product upgrades, and end-of-life management. This ensures that the product continues to perform optimally even after it has reached the end user. After-sales support can also include warranty management, where the EMS company handles warranty claims and repairs on behalf of the OEM.

Benefits of Working with an EMS Provider

Choosing to partner with an Electronics Manufacturing Services (EMS) provider can bring a multitude of benefits to Original Equipment Manufacturers (OEMs). These benefits extend beyond just cost savings, providing value in areas such as quality, efficiency, and innovation. Let’s explore some of the key benefits of working with an EMS provider.

- Cost Savings

Working with an EMS provider can result in significant cost savings. By leveraging their purchasing power, EMS providers can procure components at lower costs. Additionally, the cost of maintaining and upgrading manufacturing facilities and equipment is spread across multiple clients, resulting in lower costs for each individual client.

- Scalability

EMS providers offer scalability, allowing you to easily ramp up or scale down production based on demand. This flexibility can be particularly beneficial for companies that experience seasonal demand fluctuations or those that are launching a new product and are unsure of the market response.

- Focus on Core Competencies

By outsourcing the manufacturing process to an EMS provider, OEMs can focus on their core competencies, such as product design and marketing. This can result in improved efficiency and effectiveness in these areas, leading to a stronger competitive position in the market.

- Speed to Market

With their expertise and resources, EMS providers can significantly reduce the time it takes to bring a product from concept to market. This faster time-to-market can provide a crucial competitive advantage, particularly in industries where technology evolves rapidly.

Choosing an EMS Partner

Selecting the right Electronics Manufacturing Services (EMS) partner is a critical decision that can significantly impact the success of your product. It’s not just about finding a company that can manufacture your product, but about finding a partner that can add value at every stage of the product lifecycle. Here are some key factors to consider when choosing an EMS partner.

Technical Capabilities and Expertise

The EMS partner should have the technical capabilities and expertise to meet your specific manufacturing needs. This includes the ability to manufacture complex PCBs, perform advanced assembly techniques, and conduct rigorous testing and quality assurance. For instance, if you’re in the medical device industry, you’ll need a partner with experience in manufacturing medical-grade PCBs and adhering to stringent quality standards. They should also be able to handle the miniaturization of components, a common requirement in this industry.

Quality Certifications

Look for an EMS partner that holds relevant quality certifications. This demonstrates their commitment to delivering high-quality products and their adherence to industry standards. For example, certifications like ISO9001, ISO14001, IATF 16949, UL, and RoHS compliant are indicators of a company’s commitment to quality. If you’re in the aerospace industry, you might also look for a partner with AS9100 certification, which is specific to the aerospace industry.

Supply Chain Management

A strong supply chain is crucial in today’s globalized world. Your EMS partner should have robust supply chain management processes in place to ensure a steady supply of components and timely delivery of the final product. If you’re in an industry that’s prone to component shortages, like automotive or consumer electronics, this becomes even more important. They should have strong relationships with suppliers and contingency plans in place to handle any potential supply chain disruptions.

After-Sales Support

After-sales support is a key aspect of the services offered by an EMS partner. They should provide comprehensive after-sales support, including repair services, product upgrades, and end-of-life management. This is particularly important if you’re selling consumer-facing products, where customer satisfaction can significantly impact your brand reputation. They should be able to handle warranty claims, repairs, and product recalls efficiently and professionally.

Local Presence

Having a local presence can be a significant advantage. This can facilitate better communication, faster response times, and easier resolution of any issues that may arise. For instance, if you’re a US-based company, working with an EMS provider like Rowsum, which has an office and a dedicated business manager in the US, can provide personalized service and support.

Now, we’re excited to share a real-life example of how Rowsum has helped a client succeed. A US-based tech startup was developing a new IoT device and was looking for an EMS partner who could not only manufacture their product but also provide value-added services like design assistance, supply chain management, and after-sales support. After evaluating several options, they chose us, Rowsum. What set us apart was not just our technical expertise and quality certifications, but also our local presence in the US. This meant that the startup had a dedicated point of contact who understood their needs and could address any issues promptly. The result? A successful product launch, rave reviews from customers, and a strong ongoing partnership between the startup and us, Rowsum.

Trends and Opportunities in the Electronics Manufacturing Industry

The electronics manufacturing industry is a dynamic and rapidly evolving field, with new trends and opportunities emerging all the time. Staying ahead of these trends and capitalizing on these opportunities is key for any EMS company looking to thrive in this industry. Let’s take a closer look at some of the most significant trends and opportunities currently shaping the electronics manufacturing industry.

1. Increase in Demand for Smart Devices

The demand for smart devices, including smartphones, smartwatches, and smart home devices, has been growing at an unprecedented rate. This surge in demand is driven by several factors, including increased connectivity, the rise of the Internet of Things (IoT), and changing consumer preferences. As more and more devices become “smart,” the opportunities for EMS companies to provide specialized manufacturing services for these devices are growing as well. EMS companies that can offer high-quality, efficient manufacturing services for smart devices will be well-positioned to capitalize on this trend.

2. Growth of Wearable Technology

Wearable technology is another area experiencing significant growth. Devices such as fitness trackers, smartwatches, and virtual reality headsets are becoming increasingly popular, and this trend shows no signs of slowing down. As the technology continues to improve and become more affordable, the market for wearable devices is expected to grow even further. This presents a huge opportunity for EMS companies that can develop and manufacture innovative, high-quality wearable devices.

3. The Emergence of 5G Technology

5G technology is set to revolutionize the electronics manufacturing industry. This latest innovation in telecommunications promises faster data speeds, lower latency, and improved reliability, leading to a new generation of devices that are more powerful and efficient. EMS companies that can adapt to these changes and develop and manufacture devices compatible with 5G technology will have a significant advantage in the market.

4. Expansion of E-Commerce

The rise of e-commerce is another trend that’s having a significant impact on the electronics manufacturing industry. As more people turn to online shopping, the demand for devices that facilitate this process, such as smartphones and laptops, is increasing. This trend presents a huge opportunity for EMS companies to develop and produce innovative devices that meet the changing needs of consumers.

5. Growth of Renewable Energy Sources

Renewable energy sources such as solar and wind power are becoming increasingly popular, and this trend is expected to continue in the coming years. As more people turn to renewable energy sources to power their homes and businesses, the demand for electronic devices such as solar panels and wind turbines is expected to grow. EMS companies that can develop and manufacture innovative devices compatible with renewable energy sources will have a significant advantage in the market.

6. Increasing Importance of Sustainability

Sustainability is becoming increasingly important in the electronics manufacturing industry. Consumers are becoming more conscious of the environmental impact of the products they buy, and companies are under increasing pressure to reduce their environmental footprint. EMS companies that can demonstrate a commitment to sustainability, through practices such as using environmentally friendly materials and reducing waste, will have a competitive advantage.

7. Rise of Industry 4.0 Technologies

Industry 4.0 technologies, such as automation, artificial intelligence, and the Internet of Things, are transforming the electronics manufacturing industry. These technologies are enabling EMS companies to improve efficiency, reduce costs, and deliver higher quality products. EMS companies that can successfully integrate these technologies into their operations will be well-positioned to succeed in the future.

In conclusion, the electronics manufacturing industry is a dynamic and rapidly evolving industry that is poised for growth and is filled with opportunities for companies and investors alike. Companies that can keep up with the latest trends and can produce high-quality and innovativedevices will thrive in this industry. With the rise of smart devices, wearable technology, 5G technology, e-commerce, renewable energy sources, sustainability, and Industry 4.0 technologies, the electronics manufacturing industry is expected to grow significantly in the coming years, providing a huge opportunity for companies to succeed.

Conclusion

The electronics manufacturing services industry is a dynamic and rapidly evolving field. With the rise of smart devices, wearable technology, 5G technology, e-commerce, renewable energy sources, sustainability, and Industry 4.0 technologies, the industry is expected to grow significantly in the coming years. Companies that can keep up with these trends and produce high-quality and innovative devices will thrive in this industry.

At Rowsum, we pride ourselves on our ability to stay ahead of these trends and provide our clients with high-quality, innovative solutions. Whether you’re a small startup or a large corporation, we can provide you with the EMS services you need to succeed in this rapidly evolving industry.

For more insights into the electronics manufacturing industry, check out these articles on our blog:

- Exploring the Top 10 Applications of PCBs in Various Industries

- 94V0 Circuit Boards: The Hidden Powerhouse in Your Everyday Tech

- The Hidden Key to Longer-Lasting Electronics: Tenting Via in PCB!

Frequently Asked Questions

1. What are Electronics Manufacturing Services (EMS)?

Electronics Manufacturing Services (EMS) are services provided by companies that design, assemble, produce, and test electronic components and printed circuit board (PCB) assemblies for original equipment manufacturers (OEMs).

2. What are the benefits of working with an EMS provider?

Working with an EMS provider can offer several benefits, including cost savings, access to specialized expertise and equipment, improved product quality, and faster time-to-market.

3. How do I choose an EMS partner?

Choosing an EMS partner involves considering several factors, including the company’s capabilities, quality standards, industry experience, and customer service. It’s also important to consider the company’s financial stability and commitment to innovation.

4. What trends are shaping the EMS industry?

Key trends shaping the EMS industry include the rise of smart devices, wearable technology, 5G technology, e-commerce, renewable energy sources, sustainability, and Industry 4.0 technologies.

5. How does Rowsum stay ahead of industry trends?

At Rowsum, we stay ahead of industry trends by continuously investing in new technologies and training our team to stay up-to-date with the latest industry developments. We also work closely with our clients to understand their needs and provide innovative solutions that meet these needs.

Get Access Now: www.rowsum.com