Introduction

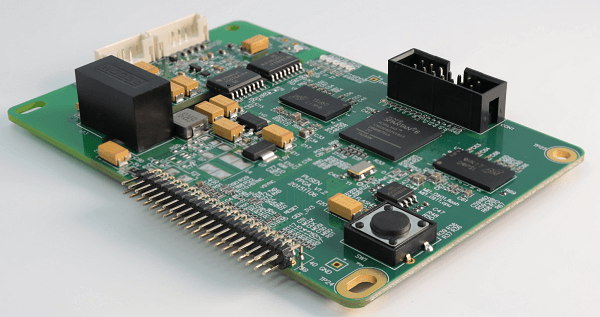

Have you ever wondered about the tiny components that power the electronic devices we use every day? How does your smartphone manage to perform complex tasks, or your car’s navigation system guide you to your destination? What about the medical devices that monitor your health or the security systems that keep your home safe? At the heart of all these technologies lie Printed Circuit Boards (PCB), unsung heroes of the modern digital age.

PCBs are everywhere, silently shaping our world by enabling the functionality of countless electronic devices. From the smallest handheld gadget to the largest industrial machinery, PCBs are the backbone of today’s technological landscape. But what exactly are these components, and where are they most commonly used? In this article, we delve into the top 10 applications of PCB manufacturing, providing you with an in-depth understanding of their crucial role in various industries. So, whether you’re a curious reader, a procurement manager like Thomas Miller, or a tech enthusiast, stay with us as we explore the fascinating world of PCB.

What is a PCB?

A Printed Circuit Board (PCB) is a thin board made of fiberglass, composite epoxy, or other laminate material. Conductive pathways, or tracks, are etched or “printed” onto the board. These tracks connect different components like transistors, resistors, and integrated circuits, enabling an electronic device to perform its function.

Types of PCBs:

- Single-sided PCBs: The simplest kind, with components on one side and conductive tracks on the other.

- Double-sided PCBs: Have components and tracks on both sides, allowing for more complex circuit designs.

- Multilayer PCBs: Consist of several layers of PCBs stacked together, ideal for intricate electronic systems.

PCBs can also be categorized based on rigidity:

- Rigid PCBs: Solid, inflexible boards used in most electronic devices.

- Flexible PCBs: Made from materials like plastic, can bend without causing damage.

- Rigid-flex PCBs: Combine the features of both rigid and flexible PCBs.

PCB Assembly Methods:

- Thru-hole mounting: Components are attached by inserting their leads through pre-drilled holes. It provides strong physical bonds but is time-consuming.

- Surface mounting: Components are soldered directly onto the PCB surface. It’s faster and allows for smaller, more complex devices.

Understanding the basics of PCBs is the first step in appreciating their wide-ranging applications. As we delve into the top 10 applications of PCB manufacturing, you’ll see just how integral these components are in various industries.

The Role of PCBs in Various Industries

Because so many different sectors use PCBs, you can find them almost everywhere in everything from small consumer devices to huge pieces of machinery. Where are printed circuit boards used? Here are 10 of the most common PCB applications by industry.

1. Medical Devices

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Implantable Devices | Devices such as pacemakers and ICDs | Highly reliable, compact, biocompatible | Must withstand body’s internal environment, long lifespan | Miniaturization, wireless charging, biodegradable PCBs |

| Diagnostic Equipment | Devices such as MRI machines, CT scanners, ultrasound machines | Can process complex signals, withstand high-frequency operations | High precision, noise reduction | AI integration, portable devices |

| Monitoring Devices | Devices such as ECG machines, blood glucose monitors | Can accurately process and relay sensitive data | User-friendly interfaces, data security | Wearable devices, real-time monitoring |

| Therapeutic Devices | Devices such as TENS machines, light therapy devices | Can deliver precise control, reliable performance | Safety, user comfort | Personalized therapy, smart devices |

| Surgical Instruments | Devices such as robotic surgical systems | Highly reliable, precise | High precision, safety | Robotic surgery, remote surgery |

| Prosthetics | Devices such as electronic limbs | Durable, compact, biocompatible | Must withstand physical stress, long lifespan | Advanced control systems, sensory feedback |

| Drug Delivery Systems | Devices such as insulin pumps | Reliable, precise control | Safety, user comfort | Smart systems, remote monitoring |

| Imaging Systems | Devices such as endoscopes | Can process complex signals, compact | High precision, noise reduction | Miniaturization, advanced imaging techniques |

Real-world example: Consider the case of implantable cardioverter-defibrillators (ICD). These devices, implanted in patients with heart conditions, use PCBs to monitor heart rhythm and deliver electric shocks to correct irregular heartbeats. The PCBs in these devices must be highly reliable, compact, and biocompatible.

Technical depth: The PCBs in ICDs often use high-density interconnect (HDI) technology to accommodate the complexity and miniaturization of medical electronics. They must also be designed to withstand sterilization processes and operate reliably in the harsh environment of the human body.

Future trends: Looking ahead, we might see the development of bio-absorbable PCB for temporary implants. These PCBs could perform a specific function, like delivering medication or monitoring a condition, and then safely dissolve in the body over time.

2. LEDs

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Lighting Systems | Devices such as LED bulbs, tubes, and panels | Heat dissipation, compact | Energy efficiency, lifespan | Smart lighting, energy-efficient designs |

| Display Panels | Devices such as LED TVs, digital billboards | High brightness, color accuracy | High resolution, energy efficiency | Flexible displays, micro-LEDs |

| Automotive Lighting | Devices such as headlights, tail lights | Durable, heat dissipation | Safety, durability | Smart lighting, energy-efficient designs |

| Indicator Lights | Devices such as status indicators, warning lights | Compact, reliable | Visibility, durability | Smart indicators, energy-efficient designs |

| Medical Lighting | Devices such as surgical lights, phototherapy lamps | High-intensity, reliable | Safety, lifespan | Advanced lighting techniques, energy-efficient designs |

Real-world example: LEDs are extensively used in automotive lighting. Modern vehicles use LEDs for headlights, taillights, interior lighting, and dashboard displays. The PCBs in these applications must be robust, able to withstand harsh environmental conditions, and manage the high heat output of LEDs.

Technical depth: The design of PCBs for automotive LED applications often involves the use of metal-core PCB, which provide superior heat dissipation compared to traditional PCB materials. The layout of the LED components and the design of the thermal path are critical factors that can influence the performance and lifespan of the LED.

Future trends: As autonomous vehicles become more prevalent, we might see the development of smart LED lighting systems that can adjust based on environmental conditions or communicate with other vehicles. This would require the development of PCBs with integrated sensors and advanced communication capabilities.

3. Consumer Electronics

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Smartphones | Devices such as mobile phones, tablets | Compact, high performance | Miniaturization, heat dissipation | Foldable devices, AI integration |

| Home Appliances | Devices such as refrigerators, washing machines | Durable, reliable | Safety, energy efficiency | Smart appliances, energy-efficient designs |

| Gaming Systems | Devices such as game consoles, VR headsets | High performance, heat dissipation | High resolution, latency | Cloud gaming, VR/AR integration |

| Wearable Devices | Devices such as smartwatches, fitness trackers | Compact, flexible | Comfort, biocompatibility | Health monitoring, flexible designs |

| Audio Equipment | Devices such as speakers, headphones, music players | High-quality audio signals | Sound quality, compact design | Wireless audio, smart devices |

| Smart Home Devices | Devices such as smart thermostats, home security systems | Wireless communication, sensor integration | User-friendly interfaces, data security | AI integration, energy-efficient designs |

Real-world example: Consider the case of smartwatches. These devices require small, flexible PCBs that can support a wide range of functionalities, from fitness tracking to mobile payments.

Technical depth: The manufacturing of PCBs for smartwatches involves the use of flexible PCB, which can conform to the shape of the watch and withstand the stresses of daily wear. The choice of materials and the design of the flex circuits are critical factors that can influence the performance and durability of the smartwatch.

Future trends: As wearable technology continues to evolve, we might see the development of smart clothing with integrated electronic functionalities. This would require the development of textile-friendly PCBs that are flexible, washable, and comfortable to wear.

4. Telecommunications

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Network Equipment | Devices such as routers, switches | High speed, reliable | Signal integrity, heat dissipation | 5G technology, energy-efficient designs |

| Satellite Systems | Devices such as satellite phones, GPS devices | Durable, high performance | Signal integrity, durability | Satellite internet, miniaturization |

| Base Stations | Devices such as cell towers, radio stations | High power, durable | Signal integrity, heat dissipation | 5G technology, energy-efficient designs |

| Communication Devices | Devices such as radios, walkie-talkies | Compact, reliable | Signal integrity, durability | Digital communication, energy-efficient designs |

| Data Centers | Devices such as servers, storage systems | High-speed data transmission, high power loads | Heat dissipation, data security | Cloud computing, energy-efficient designs |

| Fiber Optic Systems | Devices such as fiber optic transceivers, switches | High-speed optical communication | Signal integrity, durability | High-speed internet, energy-efficient designs |

Real-world example: Consider the case of cellular base stations. These devices, which form the backbone of our cellular networks, rely on PCBs to process and transmit signals over long distances.

Technical depth: The PCBs in base stations often use multi-layer technology to accommodate the high-frequency signals used in telecommunications. They must also be designed to withstand harsh environmental conditions and operate reliably 24/7.

Future trends: As we move towards 5G and beyond, we can expect to see the development of PCB that can support higher frequencies and data rates. This will require advancements in materials and manufacturing techniques to reduce signal loss and interference.

5. Automotive

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Engine Control Units | Devices that control a series of actuators to ensure optimal engine performance | High temperature resistance, vibration resistance | High precision, durability | Autonomous vehicles, energy-efficient designs |

| Infotainment Systems | Devices such as car radios, navigation systems, and rear-seat entertainment systems | High-speed data transmission, compact | User-friendly interfaces, heat dissipation | Smart systems, wireless connectivity |

| Safety Systems | Devices such as airbag controllers and anti-lock brake systems | Highly reliable, durable | Safety, reliability | Advanced safety features, autonomous vehicles |

| Power Systems | Devices such as battery management systems for electric vehicles | High power, heat dissipation | Safety, energy efficiency | Electric vehicles, energy-efficient designs |

Real-world example: Consider the case of electric vehicles (EVs). These vehicles rely on PCBs for various functions, from managing the battery system to controlling the electric motor.

Technical depth: The PCBs in EVs often use high-power, high-temperature materials to withstand the harsh operating conditions. They must also be designed to handle high currents and voltages, and provide reliable performance over the vehicle’s lifetime.

Future trends: As autonomous driving technology advances, we can expect to see the development of PCBs with integrated sensors and advanced processing capabilities. These PCBs will play a critical role in processing the vast amounts of data required for autonomous driving.

6. Aerospace

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Navigation Systems | Devices such as GPS devices and flight management systems | High precision, reliable | High precision, durability | Advanced navigation features, autonomous systems |

| Communication Systems | Devices such as radios and satellite communication systems | Durable, high performance | Signal integrity, durability | Secure communication, digital communication |

| Flight Control Systems | Devices such as autopilot systems and flight control computers | Highly reliable, high performance | Safety, reliability | Autonomous systems, advanced flight control systems |

| Surveillance Systems | Devices such as radar systems and unmanned aerial vehicles | High-speed data transmission, durable | Signal integrity, durability | AI integration, autonomous systems |

Real-world example: Consider the case of satellites. These devices, which orbit the Earth, rely on PCBs for various functions, from processing signals to controlling the satellite’s orientation.

Technical depth: The PCBs in satellites must be designed to withstand the harsh conditions of space, including extreme temperatures and radiation. They often use radiation-hardened materials and special design techniques to ensure reliable operation.

Future trends: As the demand for smaller, cheaper satellites grows, we can expect to see the development of miniaturized PCBs with high-density interconnects. These PCBs will enable the design of smaller satellites without compromising on performance.

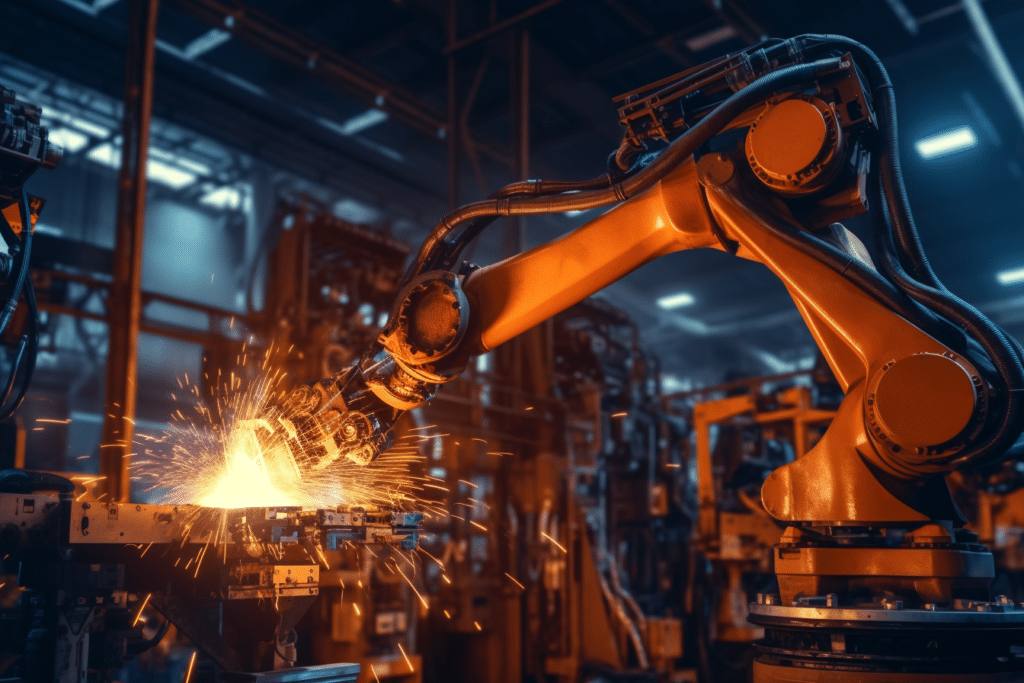

7. Industrial Control

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Automation Systems | Devices such as programmable logic controllers (PLCs) and industrial robots | Durable, high performance | Safety, durability | AI integration, smart factories |

| Process Control | Devices such as temperature controllers and pressure controllers | Reliable, precise control | High precision, safety | Real-time monitoring, smart systems |

| Power Systems | Devices such as power supply units and motor controllers | High power, durable | Safety, energy efficiency | Energy-efficient designs, smart grids |

| Instrumentation | Devices such as oscilloscopes and multimeters | High precision, reliable | High precision, durability | Portable devices, wireless connectivity |

Real-world example: Consider the case of automated assembly lines. These systems, which are used to manufacture a wide range of products, rely on PCBs to control the various machines and processes.

Technical depth: The PCBs in industrial control systems often use rugged materials and design techniques to withstand harsh industrial environments. They must also provide reliable performance under conditions of high temperature, vibration, and electrical noise.

Future trends: As Industry 4.0 advances, we can expect to see the development of PCBs with integrated sensors and IoT capabilities. These PCBs will enable real-time monitoring and control of industrial processes, improving efficiency and productivity.

8. Military and Defense

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Communication Systems | Devices such as radios and satellite communication systems | Durable, high performance | Signal integrity, durability | Secure communication, digital communication |

| Weapon Systems | Devices such as missile guidance systems and electronic countermeasure systems | Highly reliable, high performance | Safety, reliability | Autonomous systems, advanced weapon systems |

| Surveillance Systems | Devices such as radar systems and unmanned aerial vehicles | High-speed data transmission, durable | Signal integrity, durability | AI integration, autonomous systems |

| Navigation Systems | Devices such as GPS devices and inertial navigation systems | High precision, reliable | High precision, durability | Advanced navigation features, autonomous systems |

Real-world example: Consider the case of radar systems. These systems, which are used for surveillance and target detection, rely on PCBs to process and transmit high-frequency signals.

Technical depth: The PCBs in military applications must meet stringent standards for reliability and performance. They often use high-frequency materials and special design techniques to ensure signal integrity and reduce interference.

Future trends: As electronic warfare and cyber security become increasingly important, we can expect to see the development of PCBs with advanced security features. These could include hardware encryption, tamper detection, and secure boot capabilities.

9. Power Electronics

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Power Supplies | Devices such as power supply units and battery management systems | High power, durable | Safety, energy efficiency | Energy-efficient designs, smart grids |

| Motor Drives | Devices such as motor controllers and inverters | High power, heat dissipation | Safety, energy efficiency | Electric vehicles, energy-efficient designs |

| Power Conversion | Devices such as converters and rectifiers | High power, reliable | High precision, safety | Energy-efficient designs, smart grids |

| Power Protection | Devices such as surge protectors and circuit breakers | High power, durable | Safety, reliability | Smart systems, energy-efficient designs |

Real-world example: Consider the case of power inverters. These devices, which convert DC power to AC power, rely on PCBs to control the conversion process and manage the power flow.

Technical depth: The PCBs in power electronics often use high-power, high-temperature materials to withstand the high currents and voltages involved. They must also provide efficient heat dissipation to ensure reliable operation.

Future trends: As the demand for renewable energy and electric vehicles grows, we can expect to see the development of PCBs with higher power densities and efficiencies. This will require advancements in materials and manufacturing techniques to handle higher power levels and reduce losses.

10. Internet of Things (IoT)

| Application | Description | PCB Requirements | Unique Challenges | Future Trends |

|---|---|---|---|---|

| Smart Home Devices | Devices such as smart thermostats and home security systems | Wireless communication, sensor integration | User-friendly interfaces, data security | AI integration, energy-efficient designs |

| Wearable Devices | Devices such as smartwatches, fitness trackers | Compact, flexible | Comfort, biocompatibility | Health monitoring, flexible designs |

| Industrial IoT | Devices such as industrial sensors and actuators | Durable, reliable | Safety, durability | AI integration, smart factories |

| Connected Vehicles | Devices such as connected car systems and autonomous vehicles | High performance, reliable | Safety, reliability | Autonomous vehicles, smart systems |

Real-world example: Consider the case of smart home devices. These devices, which provide automated control of various home functions, rely on PCBs for processing, connectivity, and control.

Technical depth: The PCBs in IoT devices often use low-power, compact designs to enable long battery life and small form factors. They must also provide reliable wireless connectivity to communicate with other devices and the cloud.

Future trends: As the IoT continues to expand, we can expect to see the development of PCBs with integrated sensors, AI capabilities, and advanced power management features. These will enable more intelligent, energy-efficient, and versatile IoT devices.

The Future of PCBs in These Industries

As we look ahead, the future of PCBs across these industries is set to be shaped by several key trends:

1. Miniaturization and High-Density Interconnects

As devices become smaller and more powerful, the demand for miniaturized PCBs with high-density interconnects (HDIs) will continue to grow. This trend is particularly relevant in industries such as consumer electronics, medical devices, and IoT, where compact size and high performance are critical.

2. Flexible and Stretchable PCBs

The development of flexible and stretchable PCBs will open up new possibilities for wearable devices, smart clothing, and flexible electronics. These PCBs can be bent, folded, or stretched without affecting their performance, making them ideal for applications that require flexibility and conformability.

3. Advanced Materials

The use of advanced materials, such as high-frequency laminates, high-temperature substrates, and metal-core PCBs, will become increasingly important. These materials can offer improved performance in terms of signal integrity, thermal management, and durability.

4. Integrated Sensors and IoT Capabilities

The integration of sensors and IoT capabilities into PCBs will enable more intelligent and connected devices. This trend is particularly relevant in industries such as industrial control, automotive, and IoT, where real-time monitoring and control are critical.

5. Green and Sustainable Manufacturing

As sustainability becomes a more pressing concern, the PCB industry will need to focus on green and sustainable manufacturing practices. This could include the use of eco-friendly materials, energy-efficient manufacturing processes, and recycling programs.

In conclusion, the future of PCBs in these industries is set to be exciting and transformative. As technology continues to advance, PCBs will play a crucial role in enabling new innovations and driving progress across a wide range of industries.

Conclusion

In the rapidly evolving world of technology, Printed Circuit Boards (PCBs) serve as the backbone, enabling advancements across a multitude of industries. From medical devices and LED lighting to consumer electronics and the Internet of Things, the applications of PCBs are as diverse as they are transformative. As we look to the future, trends like miniaturization, flexible PCBs, advanced materials, integrated sensors, and sustainable manufacturing are set to drive the next wave of innovation.

As we navigate this exciting landscape, partnering with a reliable and forward-thinking PCB manufacturer becomes crucial. Rowsum, a leading PCB & PCBA manufacturer based in China, is committed to staying at the forefront of these trends. With a focus on quality, reliability, and customer service, Rowsum offers high-quality PCB products that meet the unique needs of various industries.

Whether you’re a procurement manager seeking efficient, cost-effective solutions, or a tech enthusiast curious about the future of PCBs, Rowsum is ready to support your journey. With our automated production line, technical expertise, and commitment to customer satisfaction, we strive to deliver solutions that align with your business goals and drive technological progress.

To learn more about us and how we can support your PCB needs, visit our website at www.rowsum.com.

By understanding the applications and future trends of PCBs, we can better appreciate the pivotal role they play in our daily lives and the vast potential they hold for the future. As we continue to explore and innovate, the possibilities are truly limitless.

If you found this article on the top applications for PCBs informative and are interested in learning more about the world of PCBs, we have several other articles that you might find valuable:

- 94V0 Circuit Boards: The Hidden Powerhouse in Your Everyday Tech: Dive deeper into the specifics of 94V0 circuit boards, a type of PCB known for its flame resistance that’s commonly used across various industries.

- The Hidden Key to Longer-Lasting Electronics: Tenting Via in PCB!: Discover the importance of tenting via in PCB design, a technique that can significantly enhance the longevity of your electronic devices.

- PCB Trace Design: The Essential Guide That Will Blow Your Mind!: Get a comprehensive understanding of PCB trace design, a crucial aspect of PCB manufacturing that can make a significant difference in the performance of your electronic devices.