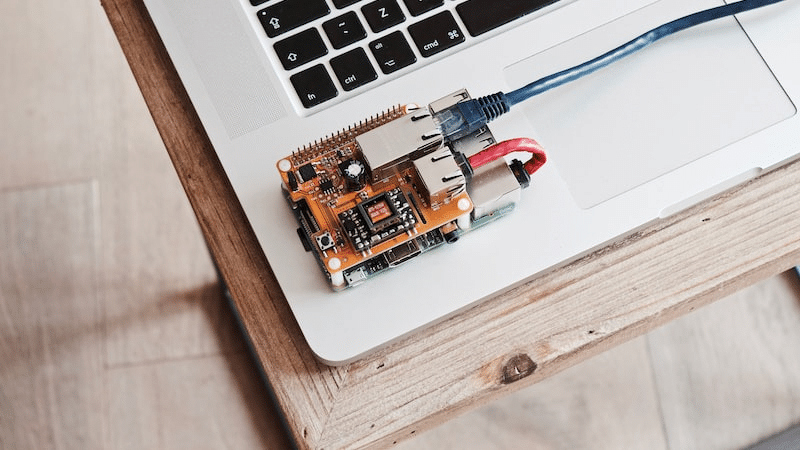

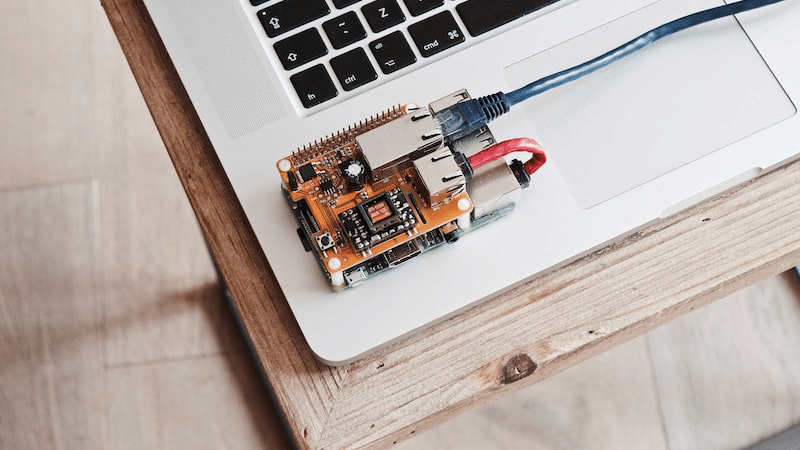

Ever wondered how your favorite gadgets manage to perform consistently despite daily wear and tear? What’s the secret behind PCBs that ensures both stability and performance? Could it be the perfect combination of fiberglass and resin that creates the foundation for high-quality PCBs?

Fiberglass and resin, also known as prepreg materials, form the core structure of a PCB, providing the essential balance between stability and performance. This dynamic duo offers electrical insulation, mechanical strength, and heat resistance, making them indispensable in modern PCB designs. Curious to find out more? Let’s unravel the mystery behind this perfect marriage!

Why are fiberglass and resin crucial for PCB stability and performance?

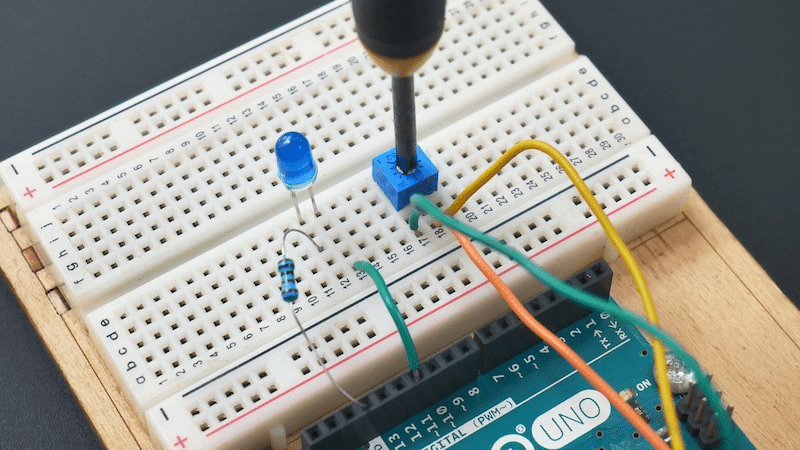

Fiberglass, a lightweight and robust material, offers exceptional mechanical strength and dimensional stability 1. Combined with resin, which acts as a binding agent, they create the perfect blend of materials that offers both rigidity and flexibility for PCBs. This ensures that the PCB can withstand mechanical stress while maintaining its form and functionality.

Resin also provides excellent electrical insulation properties, which are vital for maintaining signal integrity and preventing electrical shorts 2. Moreover, the combination of fiberglass and resin contributes to the PCB’s heat resistance, allowing it to operate efficiently even under high-temperature conditions.

How do manufacturers optimize the use of fiberglass and resin in PCBs?

Selecting the right type of fiberglass and resin for a specific application is critical in achieving optimal PCB performance. Factors such as the type of resin, fiberglass weave style, and thickness of the prepreg layer can all influence the PCB’s overall stability and performance 3.

Manufacturers must also ensure that the prepreg layers are evenly and adequately distributed throughout the PCB, avoiding voids or air bubbles that could compromise the board’s structural integrity.

What innovations are driving the future of fiberglass and resin in PCBs?

As technology evolves, so do the demands for more advanced and sophisticated PCB designs. Manufacturers must continuously explore new materials, such as high-performance resins and advanced fiberglass weaves, to meet these ever-growing requirements.

One example is the development of high-frequency, low-loss laminates that combine specialized resins with unique fiberglass weaves to achieve superior electrical performance 4. These innovations help drive the future of PCBs, allowing for more complex and powerful electronic devices.

Conclusion

In conclusion, fiberglass and resin are indeed the perfect marriage for PCB stability and performance. By carefully selecting and optimizing the use of these materials, manufacturers can create high-quality PCBs that meet the increasing demands of today’s fast-paced, technology-driven world.