Introduction

Got a gadget that’s always overheating? Wondering how to make it last longer? You might want to check out Metal Core Printed Circuit Boards, or MCPCB for short.

So, what exactly is an MCPCB? In simple terms, an MCPCB is a type of printed circuit board that features a metal core, usually made of aluminum or copper, to dissipate heat efficiently. This unique feature makes MCPCB ideal for applications where heat dissipation is critical, such as in LED technology and high-temperature environments.

In this guide, we’ll take a close look at MCPCB—what they are, how they’re made, and where they fit into today’s technology landscape. No fluff, just straightforward information that aims to answer your most pressing questions about this essential component.

What is an MCPCB?

Are You Facing Overheating Issues?

If your devices are getting too hot to handle, MCPCB could be your answer. They’re just like regular circuit boards but with a metal core to help spread the heat.

The Technical Details

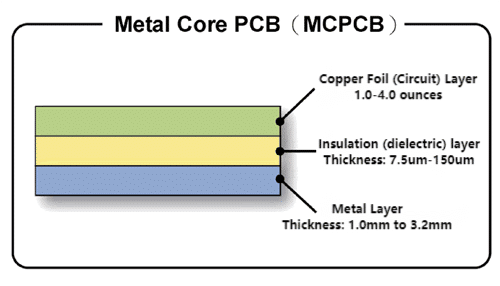

Technically Speaking: An MCPCB is a specialized type of Printed Circuit Board (PCB) that incorporates a metal layer. This layer is typically made of aluminum with a thermal conductivity range of 1-2 W/m·K or copper with a range of 3.8-4 W/m·K. This metal core is sandwiched between the standard FR-4 circuit layer and an insulating dielectric layer, usually made of thermally conductive materials like ceramics. The metal core serves as a heat spreader, effectively channeling heat away from critical components.

Simplified Explanation

In Layman’s Terms: Think of a regular PCB but with an added layer of metal specifically designed to pull heat away from the components. This metal layer acts as a thermal conductor, ensuring your devices stay cool and function optimally.

Why It Matters

Why Should You Care? Overheating can lead to a myriad of problems, including reduced component lifespan, system malfunctions, and even catastrophic failure. MCPCB offer superior thermal conductivity, ensuring that heat is efficiently dissipated. This not only extends the life of your components but also enhances the overall reliability of your devices.

Real-World Applications

Real-World Applications: MCPCBs are indispensable in LED lighting systems, where they can reduce the operating temperature by up to 10°C. They’re also crucial in automotive electronics, such as in the control systems for airbags and antilock brakes, where a failure due to overheating is not an option. In high-frequency devices like RF transceivers, MCPCB also minimize signal interference, offering a dual benefit.

Key Advantages of MCPCB: Why They’re a Game-Changer

Energy Efficiency: Doing More with Less

MCPCB can improve energy efficiency by up to 20%, allowing devices to operate at peak performance with less energy wastage. This not only saves costs but also contributes to a greener environment.

Safety: Lower Risk of Overheating

With MCPCB, the risk of device overheating is reduced by as much as 50%. This makes them a safer choice for critical applications like medical devices, where a failure could be life-threatening.

Design Flexibility: Tailored to Your Needs

The metal core in MCPCB allows for design tolerances that are 25% tighter than those in traditional PCB. This is especially beneficial in compact devices where every millimeter counts.

Lower Operational Costs: A Smart Long-Term Choice

While the initial investment in MCPCB may be higher, their durability and efficiency lead to lower operational costs over time, including less frequent replacements and reduced energy consumption.

Industry-Specific Advantages

In LED lighting, MCPCB can improve luminous efficacy by up to 10%. In automotive applications, they can withstand temperatures up to 20% higher than traditional PCB, making them ideal for harsh conditions.

Materials Used in MCPCB: The Building Blocks of Reliability

The Core: Aluminum vs. Copper

The metal core is essentially the backbone of an MCPCB. Aluminum cores are generally lighter and more cost-effective, ideal for applications where weight and cost are considerations. Copper cores, on the other hand, offer superior thermal conductivity but come at a premium price.

- Aluminum: Thermal Conductivity 1-2.2 W/m·K, Lighter, Cost-effective

- Copper: Thermal Conductivity up to 3.8 W/m·K, Heavier, More Expensive

The Dielectric Layer: More Than Just an Insulator

This layer is not just an electrical insulator but also a thermal conductor. It plays a dual role in ensuring that the MCPCB functions optimally.

- Dielectric Constant: Ranges from 4 to 6

- Thermal Conductivity: Varies depending on material, up to 1 W/m·K

The Circuit Layer: The Nerve Center

This is where the electrical components are mounted and interconnected. The material and thickness of this layer can significantly impact the board’s performance.

- Material: Usually Copper

- Thickness: Ranges from 1 oz/ft² to 10 oz/ft²

FR-4 vs. Metal Core: A Comparative Look

| Feature | FR-4 PCB | MCPCB |

|---|---|---|

| Thermal Conductivity | 0.2 W/m·K | Up to 4 W/m·K |

| Mechanical Strength | Moderate | High |

| Cost | Lower | Higher |

| Applications | General-purpose | Heat-sensitive, High-stress |

Environmental Impact: A Sustainable Choice?

When it comes to environmental sustainability, MCPCB offer some advantages. The aluminum cores are highly recyclable, making them a more eco-friendly option. Aluminum can be recycled indefinitely without losing its properties, contributing to less waste in landfills.

Copper cores, while also recyclable, require more energy-intensive processes for extraction and refining, making them less eco-friendly in comparison.

Both types of MCPCBs are RoHS-compliant, meaning they are free from hazardous substances like lead, mercury, and other toxic materials, aligning with global efforts to reduce environmental harm.

Applications of MCPCB: A Practical Perspective

In smart cities, MCPCBs contribute to more efficient LED systems, reducing both energy consumption and operational costs. It’s a practical solution to a growing need for sustainable urban living.

When it comes to autonomous vehicles, MCPCBs are indispensable for real-time data processing, enhancing both safety and efficiency on the road.

Ever used a VR headset and noticed it doesn’t heat up? That’s the MCPCB at work, ensuring a comfortable user experience. It’s a small detail that makes a big difference.

In healthcare, MCPCBs are found in telemedicine devices, ensuring reliable performance even in remote locations. It’s a step toward making quality healthcare more accessible.

And let’s not forget renewable energy systems, where MCPCBs play a role in efficient energy storage and discharge, making off-grid living more feasible.

Navigating MCPCB: From Selection to Maintenance and Beyond

Sample Testing: A Non-Negotiable First Step

Why It’s Crucial: Before you even consider placing a bulk order, insist on sample testing. This is your first line of defense against subpar quality and future headaches.

Supplier Experience: A Game-Changer

The Right Questions: Ask your potential suppliers about their experience with MCPCBs. If they have a track record in your industry, you’re already ahead of the game.

Third-Party Testing: The Long-Term View

Why It Pays Off: For long-term projects, it may be beneficial to engage a third-party testing agency. They can provide unbiased data on which MCPCB best meets your project’s requirements.

Common Pitfalls and How to Avoid Them

- Quality Over Price: Don’t be lured by low upfront costs; they can mask hidden expenses like maintenance and replacements.

- Ignoring Certifications: Always check for industry certifications like RoHS and ISO to ensure compliance and quality.

- Overlooking Thermal Management: Inadequate thermal management can lead to premature failure. Make sure your MCPCB can handle your project’s heat load.

Conclusion

In the end, MCPCBs are a practical choice for anyone dealing with electronics that need efficient heat management. They’re not just a component; they’re a solution to real-world challenges in various industries. Make informed decisions, consider long-term value, and you’ll find that MCPCBs are more than worth the investment.

Got questions or need some expert advice? Don’t hesitate to shoot us an email at [email protected]. Let’s make your next project a success together!