Rowsum Services

Rowsun PCBA: Where Every Circuit Tells a Story.

At Rowsun, we turn circuit boards into canvases, your vision into reality. Experience the art of PCB Assembly, tailored for your success.

Rowsun PCB Assembly: Where Precision Meets Your Electronic Vision.

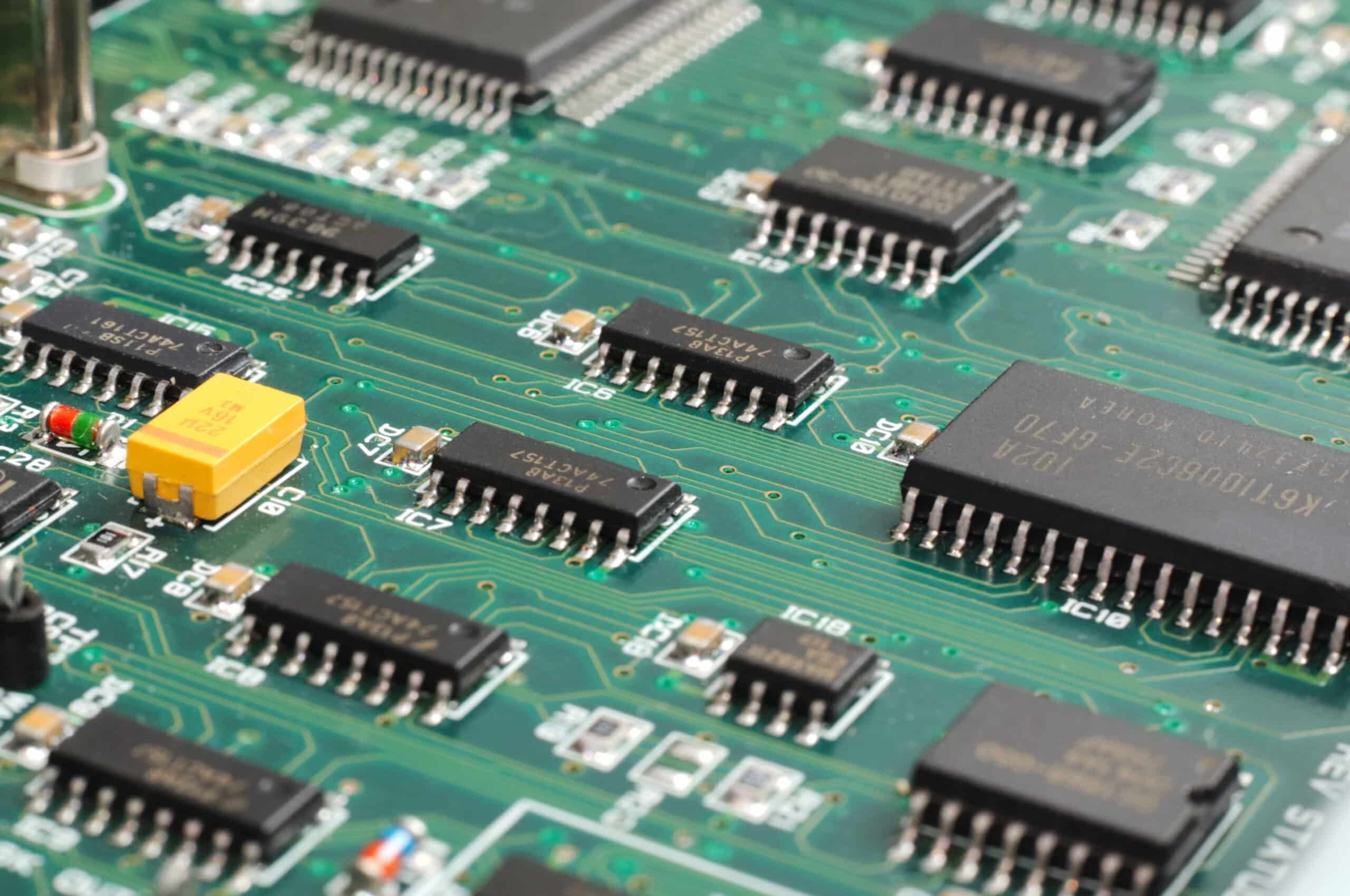

Welcome to Rowsun, where your electronic visions are transformed into tangible, high-performance products. Our comprehensive PCB assembly services cover the entire spectrum: from meticulous component sourcing and advanced PCB manufacturing to precision assembly, thorough testing, and timely shipment. We take particular pride in our expertise in assembling BGA, Micro-BGA, QFN, and other leadless package parts.

With a solid foundation in Shenzhen, China, and strategic offices in the United States, we’re in an optimal position to deliver swift, reliable, and unparalleled services to our esteemed global clientele. Our commitment to excellence is underscored by our prestigious certifications, including ISO 9001, ISO 14001, IATF 16949, and UL.

- SMT, Through Hole, and Mixed Assembly

- Passive Components Down to 01005 Sizes

- Ball Grid Array (BGA) and Ultra-Fine Ball Grid Array (uBGA)

- Quad Flat Pack No-Lead (QFN) and Quad Flat Package (QFP)

- Plastic Leaded Chip Carrier (PLCC)

- SOIC, Package-On-Package (PoP), and Small Chip Packages (Pitch of 0.2 mm)

Navigate Rowsun's PCB Assembly Services

Explore this comprehensive guide to quickly locate the information you need about our specialized services.

PCB Assembly Services: Tailored Turnaround for Every Project

From rapid PCB prototyping to large-scale PCBA production, Rowsun delivers unmatched speed and precision.

Rapid PCB Prototyping: Accelerate Your Innovations

Swift assembly services designed for immediate testing and validation.

Turnaround Time | Maximum PCBs | Maximum BOM Line Items | Maximum SMT Placements / Board | Maximum Through Hole Components per Order |

24 Hours | 8 | 15 | 70 | 8 |

48 Hours | 20 | 20 | 150 | 40 |

5 Days | 100 | 40 | 500 | 200 |

Large-Scale PCBA: Consistent Quality

Ideal for Mid to Large Runs with Quality, Scalability, and Flexibility.

Turnaround Time | Maximum PCBs | Maximum BOM Line Items | Maximum Through Hole Components per Order |

7 Days | 500 | 70 | 500 |

10 Days | 1000 | 90 | 1000 |

15 Days | 4000 | 120 | 4000 |

Schedule Shipping (No Limits) | Unlimited | Unlimited | Unlimited |

Diverse Assembly Models: Customized Solutions for Every Need

Dive deeper into Rowsun’s specialized services, each crafted to align with your project’s unique demands and specifications.

Turnkey Assembly:

Tired of juggling multiple vendors? Our Turnkey Assembly offers a one-stop solution, managing everything from component sourcing to final testing. Simplify your process and reduce overheads with Rowsun.

Prototype Assembly

Need to validate your design quickly? Our Prototype Assembly ensures your innovations are tested and refined swiftly, helping you beat competitors to market.

Production Assembly:

Scaling up and worried about consistency? Our Production Assembly guarantees uniform quality across large batches, ensuring your brand's reputation remains untarnished.

Partial Turnkey Assembly:

Want to maintain control over specific components but need help with the rest? Our Partial Turnkey Assembly lets you supply specialized parts while we handle the bulk of the assembly. Get the best of both worlds.

Consigned Assembly (Kitted):

Have a trusted component supplier but need expert assembly? With our Consigned Assembly, you provide the components, and we ensure they're assembled to perfection. Maximize your existing relationships without compromising on assembly quality.

Box Build:

Looking for an end-to-end solution? From initial assembly to final packaging, our Box Build service ensures your product is market-ready. Save time and avoid logistical headaches with Rowsun.

Re-Work and Repair:

Encountered issues with your PCBs? Our Re-Work and Repair service ensures that any defects or malfunctions are promptly addressed, restoring functionality and ensuring your products meet the highest standards.

Scheduled Shipping:

Need flexibility in your delivery timelines? With our Scheduled Shipping service, you can set delivery dates that align with your project timelines, ensuring you have the components you need, when you need them.

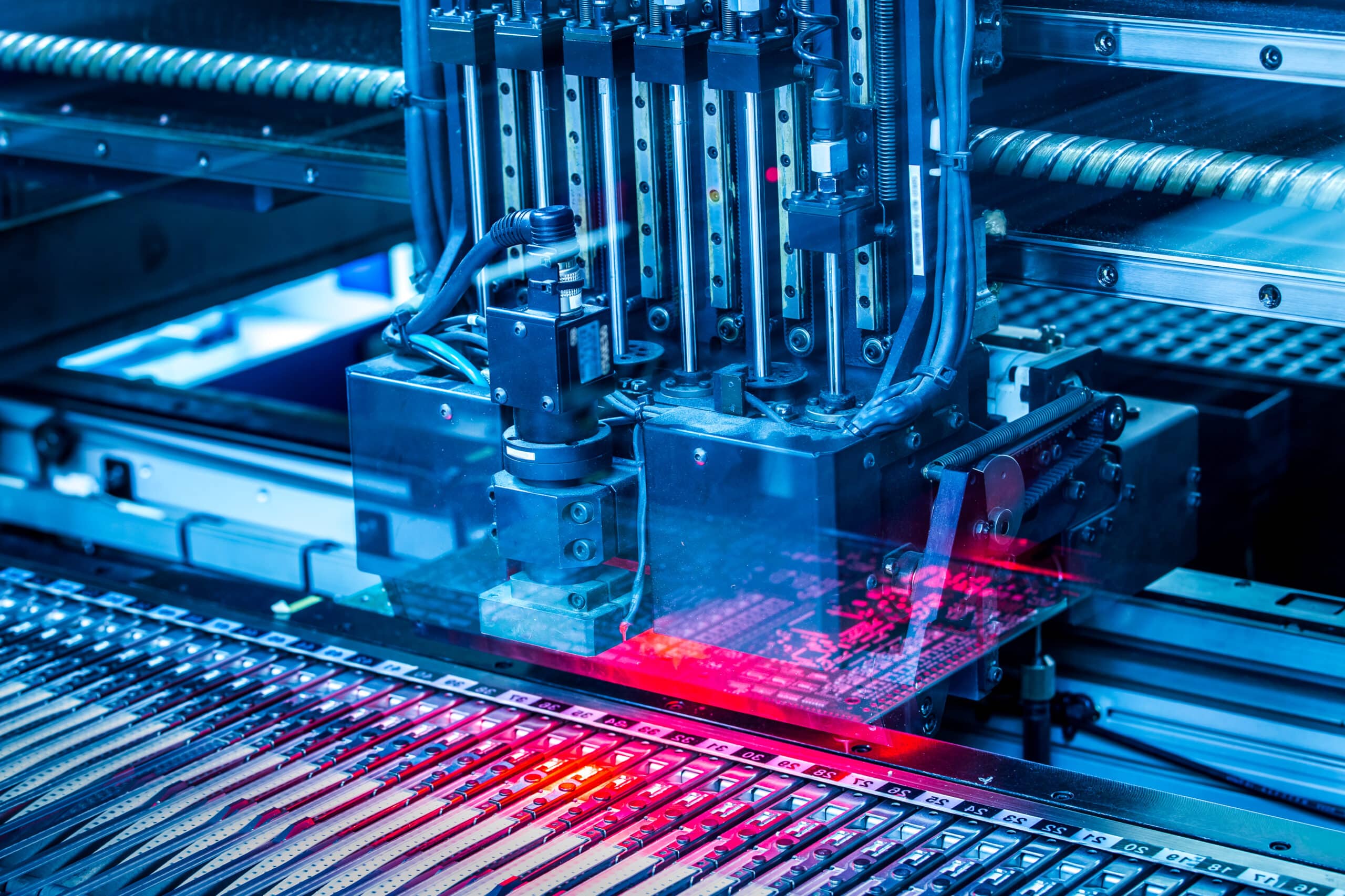

State-of-the-Art Equipment for Unmatched Precision

Discover the cutting-edge technology that powers Rowsun’s PCB Assembly Services.

Introduction to PCBA

What is PCBA?

PCBA stands for Printed Circuit Board Assembly. It’s the next phase after PCB fabrication and involves the mounting or placement of various electronic components onto the PCB. The components could be resistors, capacitors, ICs, and more. Once these components are soldered onto the board, it becomes a PCBA, which can be integrated into electronic devices to perform specific functions.

Difference between PCB and PCBA

A PCB (Printed Circuit Board) is a foundational platform that supports and connects electronic components. It’s made of layers of insulating materials with conductive pathways. PCBA, on the other hand, is the completed board with all the electronic components soldered onto it. In simple terms, PCB is the board itself, while PCBA is the board plus all its components.

THT vs. SMT

THT (Through-Hole Technology) and SMT (Surface Mount Technology) are two primary methods of mounting components onto a PCB.

– THT: In this method, components have long leads that are threaded through holes on the PCB and then soldered to pads on the opposite side. It’s a robust method, especially for components that endure mechanical stress.

– SMT: This modern method involves soldering components directly onto the surface of the PCB. It allows for smaller components, higher component density, and both sides of the board to be used, making it suitable for miniaturized and high-frequency devices.

Your Complete Guide to Rowsun's Assembly Process

Your Journey with Rowsun: From First Contact to Final Delivery

>Initial Inquiry: Reach out to us with your project details, requirements, and any specific challenges you’re facing.

>Consultation: Our team reviews your requirements and schedules a consultation to discuss the project in-depth, ensuring we understand your needs.

>Quotation: Based on the consultation, we provide a detailed quotation, outlining costs, timelines, and any recommendations for optimizing the project.

>Design Review: If you have an existing design, our engineers review it for manufacturability and suggest improvements if needed.

>Component Sourcing: We source high-quality components as per the project’s requirements, ensuring reliability and cost-effectiveness.

>Production: Your project enters our state-of-the-art production line, where it undergoes assembly, soldering, and other necessary processes.

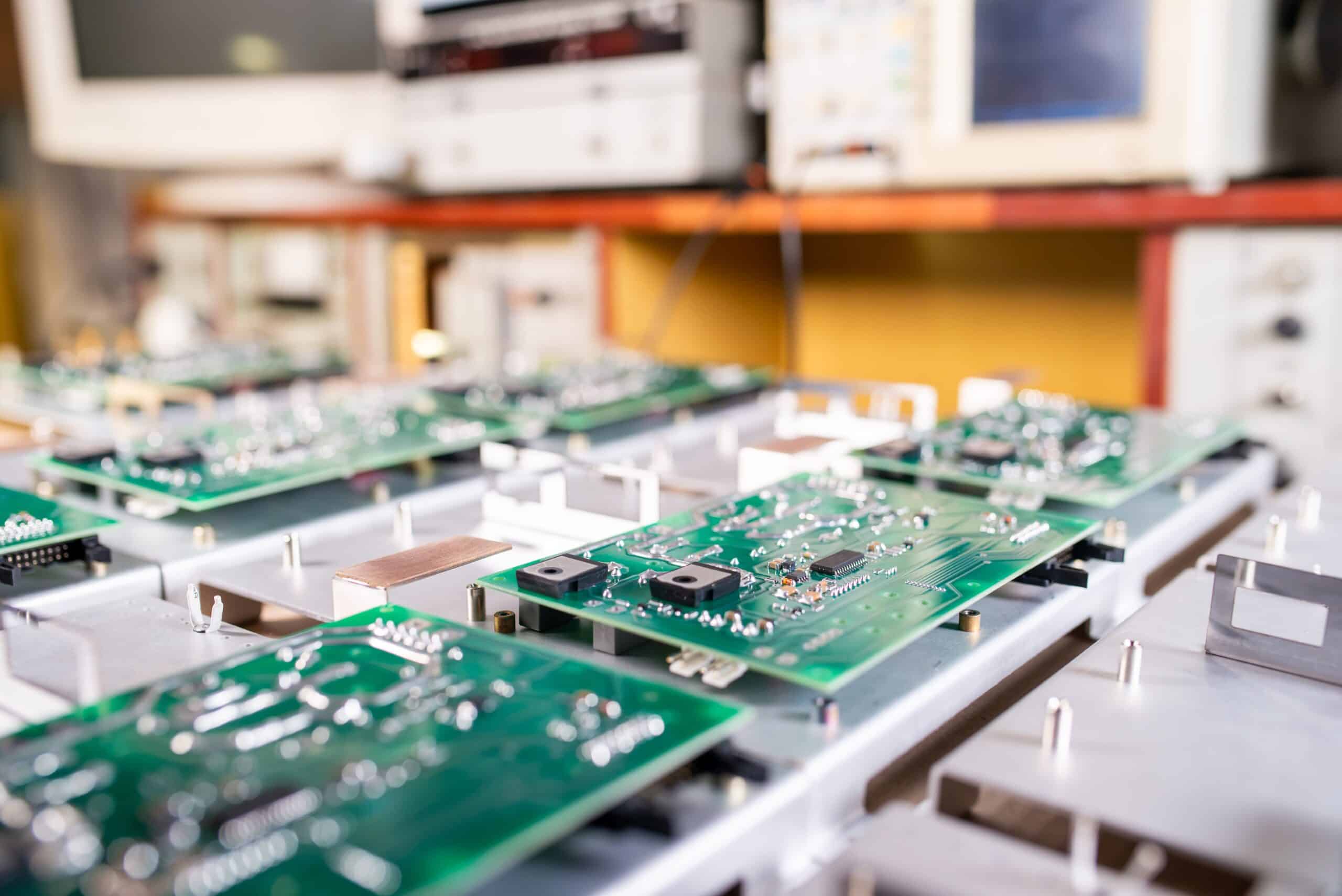

>Quality Assurance: Post-production, every unit undergoes rigorous testing and quality checks to ensure it meets Rowsun’s high standards.

>Packaging & Shipping: Once approved, products are carefully packaged to ensure safe transit and shipped to your specified location.

>After-sales Support: Our relationship doesn’t end with delivery. We offer robust after-sales support, addressing any concerns or questions you might have.

Inside Rowsun's Production: Step-by-Step Assembly Excellence

Design Input: We start with your design files and Bill of Materials (BOM). If you don’t have a design yet, our team can assist in creating one.

>Solder Paste Printing: Using our SMT Automatic Printers, we ensure precise application of solder paste to the PCB.

>Component Placement: Depending on the project’s complexity, either our High-Speed or Mid-speed Pick and Place Machines accurately place the components on the PCB.

>Reflow Soldering: The Ten-Temperature-Zone Reflow Soldering Machines provide precise control, ensuring reliable connections for every component.

>Inspection: The SMT AOI Testing Machines inspect the assembly for any defects or misplacements.

>Additional Assembly (if required): For projects requiring THT components or other specialized assembly processes, this step ensures all components are securely attached.

>Final Testing: Functional tests are conducted to ensure the assembly operates as intended.

>Packaging: Once testing confirms the assembly’s functionality, it’s prepared for delivery.

Rowsun's Process & Technical Prowess

Rowsun's PCB Capabilities: Precision and Performance at Every Layer

| ITEMS | Parameters (in metric) | Remarks | ||

| Double side/Multi-layer | ||||

| Max panel size | 32”×20”(800mm×508mm) | |||

| Innerlayer line width/space(min) | 0.075m(3mil) | |||

| Min ninnerlayer pad | 5min(0.13mm) | Pad annular (referring to the width of the solder ring) | ||

| Min core thickness | 4min(0.1mm) | |||

| Thickness of innerlater copper | 1/2oz(17um) | No copper cladding | ||

| Thickness of outerlayer base copper | 1/2oz(17um) | |||

| Thickness offinished panel | 0.20-4.0mm | |||

| Tolerance of finished panel thickness | Thickness <1.0mm | ±12% | 4-8layers | |

| 1.0≤Thickness<2.0mm | ±8% | 4-8layers | ||

| ±10% | ≥10layers | |||

| Thickness≥2.0mm | ±10% | |||

| Surface treating process of innerlayer | Brown Oxide | |||

| Layer count | 1-16L | |||

| Registration of innerlayer to of innerlayer | ±3mil(±76um) | |||

| Min diameter of finished hole | 0.2mm(8mil) excluding HDI | |||

| Accuracy of hole position | ±2mil(±50um) | |||

| Tolerance of drilled slot | ±3mil(±75um) | |||

| Tolerance of PTH diameter | ±2mil(±50um) | |||

| Tolerance of NPTH diameter | ±1mil(±25um) | |||

| MaxA.R.of PTH | 10:01 | |||

| PTH hole copper thickness | 0.4-2mil(10-50um) | |||

| Image to image tolerance | ±3mil(0.075um) | |||

| Outer layer line width/space(min) | 3mil/3mil(75um/75um) | |||

| Tolerance of etching | ±1mil(±25um) | |||

| Thickness of solder mask | Line end | 0.4-1.2mil(10-30um) | ||

| lineComer | ≥0.2mil(5um) | |||

| On Substrate | ≤finished Cu thickness+1.2mil(≤finished Cu thickness+30um) | |||

| Hardness of solder mask | 6H | |||

| Solder mask registration tolerance | ±2mil(±50um) | |||

| Min solder mask dam | 3.0mil(75um) | |||

| Max solder mask plug hole diameter | 0.6mm | |||

| Surface freatment | ||||

| HASL、gold finger、Au Panel、OSP、ENING | ||||

| Range of nickel thickness for electroless nickel and immersion gold | 120u”/240u”(3um/6um) | |||

| Range of gold thickness for electroless nickel and immersion gold | 2u”/6u”(0.05um/0.15um) | |||

| Impedance control and tolerance | ±10% | |||

| Peel strength of line | ≥61B/in(≥107g/mm) | |||

| Warp and twist | ≤0.75% | |||

| Blind Hole/buried plate | √ | |||

| Surface Treatment | Immersion gold, immersion silver, immersion tin, OSP, spray pure tin, gold plating | |||

| Substrate material | GETEK, ROGERS, Teflon, high TG, aluminum-based, FR-4 | |||

Rowsun's PCBA Capabilities: Comprehensive Assembly Expertise

| SMT Lines | 7 Lines |

| Capacity | 52 million placements per month |

| Max Board Size | 680×500mm Smallest:0.25″x0.25″ |

| Min Component size | 0201 – 54 sq. mm. (0.084 sq. inch), long connector, CSP, BGA, QFP |

| Speed | 0.15 sec/chip, 0.7 sec/QFP |

| Wave-Solder | Max. PCB width:450mm |

| Min. PCB width: no limited | |

| Component height:Top 120mm/Bot 15mm | |

| Sweat-Solder | Metal type :part, whole, inlay, sidestep |

| Metal material:Copper , Aluminum | |

| Surface Finish:plating Au, plating sliver , plating Sn | |

| Air bladder rate:less than20% | |

| Press-fit | Press range:0-50KN |

| Max. PCB size:800X600mm | |

| Quantity | No MOQ, Prototype & Low Volume PCB Assembly,And mass assembly |

| Type of Assembly | SMT and Thru-hole |

| Solder Type | Water Soluble Solder Paste,Leaded and Lead-Free |

| Components | Passives Down to 0201 Size BGA and VFBGA Leadless Chip Carrier/CSP Double-Sided SMT Assembly Fine Pitch to 08 Mil BGA Repair and ReballPart Removal and Replacement-Same Day Service |

| File Formats | Bill of Materials ,Gerber Files, Pick-N-Place File(XYRS) |

| Type of Service | Turn-Key,Partial Turn-Key or Consignment |

| Component Packaging | Cut Tape, TubeReels Loose, Parts |

| Turn Time | Same Day Service to 15 day service |

| Testing | XRAY Inspection ,AOI Testing , ICT,Probe flying,burn-in,function test,temperature cycling. |

| Our Machines | Japanese SONY high-speed SMT SI-F130WR Qty: 23 Japanese SONY multifunctional SMT SI-F209 Qty: 7 Japanese YAMAHA multifunctional SMT YV100XGP Qty: 7 DESEN Automatic silk printing machine DSP-1008 Qty: 10 YoungXin lift slab machines BL-250W-ST Qty: 8 American Heller 18 zones reflow oven Qty: 4 America PACEB BGA repair station Qty: 2 Japanese SONY AOT tester Qty: 4 3D-SPI checkout equipment Qty: 2 ChaoJinDa full-aotumatic ultrasonic cleaning machine Qty: 3 Japanese Japanese X-Ray detector Qty: 1 YongXing Industrial oven Qty: 3 Automatic double wave peak welding line Qty: 2 Automatic belt post-welding production line Qty: 5 Automatic belt assembly line Qty: 1 Automatic belt cleaning packaging line Qty: 2 Computer test maintenance equipment Qty: 15 Online AOI detection equipment Qty: 4 |

What Our Clients Say

Real Stories from Satisfied Customers

Ahmed

Head of Product Development

I’ve gotta say, Rowsun really came through for us. We were in a bind with our previous supplier, and these guys stepped up. Their Turnkey Assembly is no joke—saved us a ton of time and headaches. The team knows their stuff, and they’re easy to work with. Two thumbs up!

Isabella

Procurement Manager

when you’re a startup, you’re used to getting the short end of the stick. But that was never the case with Rowsun. Even When we were just ordering small batches and prototypes, they took us seriously. Kyle, in particular, has been a godsend. The guy’s always on the ball—quick to respond and even hooks us up with discounts. We’re actually planning a trip to China to meet the whole team, and I can’t wait to finally meet Kyle in person. We’ve become more than just business partners; we’re friends.

Mratin

Operations Director

When Leo first reached out to me, I assumed he was based in China like the rest of the Rowsun team. Imagine my surprise when he showed up at my office one day with samples in hand! That’s how Rowsun operates—always exceeding expectations. I couldn’t be happier with their service.

Explore Our Blog and Knowledge Base

Dive deeper into the world of PCB & PCBA manufacturing with our comprehensive blog and knowledge base. From detailed guides and how-tos to industry insights and tips, we’ve got you covered. Stay informed and up-to-date with Rowsum’s expertly curated content.

Top 10 PCB manufacturers in Turkey

Introduction Need to find a PCB manufacturer in Turkey? You’ve come to the right spot. I’ve looked around and put together a list of the

What Are PCB Pads? The Ultimate Guide to Types, Uses, and Design Tips

Introduction Imagine constructing an intricate Lego masterpiece without the small connectors that hold each piece in place. Frustrating, right? Now, picture these connectors failing at

We'd love to hear from you

Unlock Savings Today!

Looking to kickstart your PCBA prototype project? We typically offer discounts or even free samples to kickstart our collaboration. Fill out the form and you can expect a response within 12 hours. Get a PCB quote in as little as 2 hours and a complete PCBA project quote usually within 2 days!

Reach us through

- 398 Pennsylvania Blvd Floral Park,NY 11001

- 110, Building D, Chengshanhai · Yunhui Phase II, Xuegang South Road, Longgang District, Shenzhen

- 516-676-2100 / +86 0755-84896912

- [email protected]

Ready to Save 30% on Your Project? Contact Us Now!

Frequently Asked Questions

These are the most frequently asked questions. If you cannot find an answer here, please contact us via email at [email protected]

What is the minimum order quantity for your PCB assembly service?

We do not have a minimum order quantity. We can handle orders from first articles to prototype to production.

What types of solder do you use in your PCB assembly process?

We use both leaded and lead-free/RoHS compliant solder. We also use no-clean and water clean fluxes.

What types of components can you handle in your PCB assembly process?

We can handle a wide range of components, including those as small as 01005 sizes, as well as specialized components like Ball Grid Array (BGA), Quad Flat Package No-Lead (QFN), Quad Flat Package (QFP), and Small Chip Package with a pitch of 0.2 mm.

What other capabilities do you offer in addition to PCB assembly?

We offer rework services, wire & cable harnesses, box build, DFM Analysis, XRAY Inspection, aqueous cleaning, and PCB testing services.

What are the file requirements for PCB assembly orders?

Each order should include Gerber files, a Centroid file (also known as pick and place file), and a Bill of Materials (BOM) in Excel format.

How do you ensure the quality of your PCB assembly services?

Quality is our top priority. We employ a multi-step quality control process that includes Design for Manufacturability (DFM) checks, Automated Optical Inspection (AOI), and X-ray inspections specifically for BGA and QFN components. Additionally, we conduct functional tests tailored to each customer's unique requirements.

What options do you offer for component sourcing in PCB assembly?

We offer flexible options to meet your component sourcing needs. For turn-key solutions, we handle all component sourcing, leveraging our network of reliable suppliers to get high-quality components at competitive prices. If you prefer to supply some or all of the components yourself, we can also accommodate that. We're here to work with you to find the best solution for your project.

Do you offer design services for PCB assembly?

Our engineers primarily focus on production-related tasks. However, depending on our project load for the month, they may be available to take on design projects. If our engineers are busy, we also have long-standing partnerships with design firms that can provide comprehensive design and development services. We strive to provide the best solution for your project, whether that involves our in-house team or our trusted partners.

Why is Rowsun featured in the list of top PCBA manufacturers in the USA?

While our production facilities are based in China, we have a strong presence in the United States with our office providing real-time support to our customers in North America. This allows us to offer the cost advantages of manufacturing in China along with the convenience and service of a local American company. This unique combination has earned us a spot among the top PCBA manufacturers for many American businesses.