Introduction

What exactly is the bill of materials for PCB? It’s a crucial question that stands at the heart of efficient PCB procurement. Simply put, the bill of materials for PCB is a comprehensive list encompassing all raw materials, electronic components, assembled and semi-assembled parts, and everything else required for manufacturing a printed circuit board. This list is not just an inventory; it’s the blueprint for successful PCB fabrication.

But how does a well-prepared BOM enhance procurement efficiency? This article is dedicated to unraveling the complexities of PCB BOM and providing practical insights on optimizing procurement processes around it. We aim to guide procurement professionals in understanding, managing, and utilizing the BOM to its fullest potential, thereby streamlining their workflow and enhancing overall project success.

The Role of BOM in PCB Assembly

Procurement and Production Phases:

In PCB assembly, the Bill of Materials is indispensable not only in the procurement phase but also throughout the production process. It serves as a detailed guide for acquiring the right components and is equally crucial for the assembly line, where it ensures that each part is correctly placed and used. This comprehensive list helps streamline both the procurement and manufacturing stages, reducing the risk of errors and ensuring the project adheres to its planned timeline and budget.

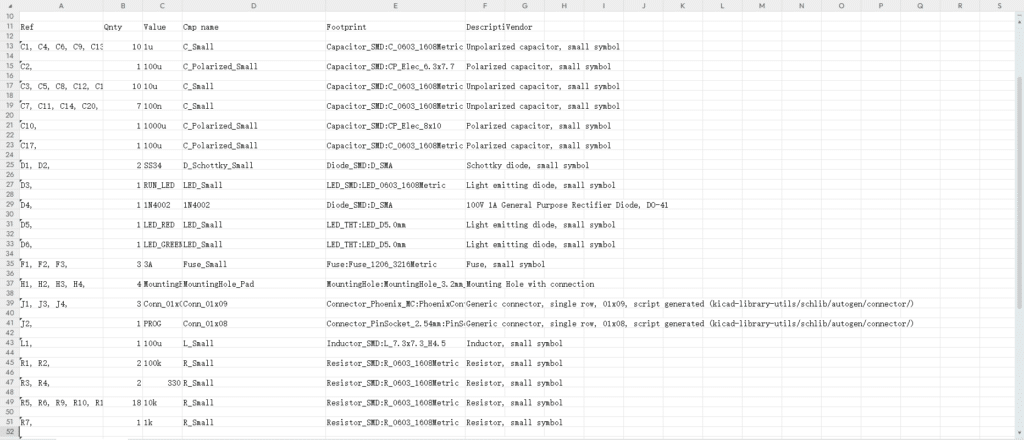

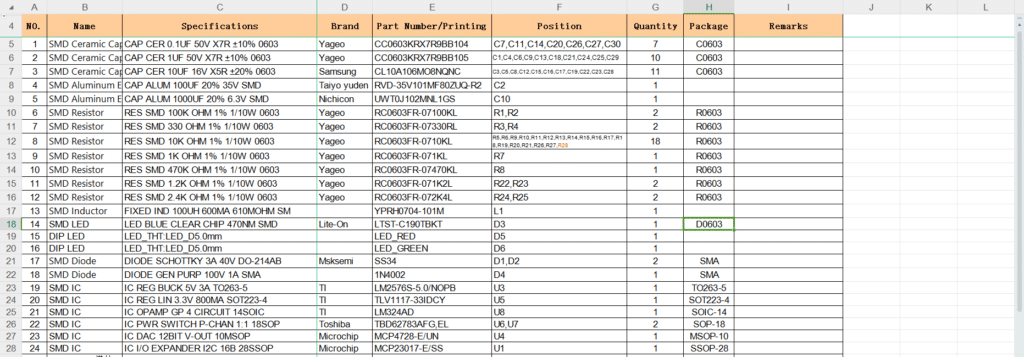

Key Components of a PCB BOM

- 1. Part Numbers: Each component’s unique identifier is vital for ensuring the correct parts are sourced and used. This precision is key to preventing mix-ups and maintaining the integrity of the PCB design.

- 2. Manufacturers: Including the manufacturer’s name for each component helps in sourcing authentic and quality parts. It aids in quality control and can be crucial when considering warranty claims or tracking down specific components for repair or replacement.

- 3. Detailed Descriptions: Specifics such as size, color, and electrical properties are necessary to identify and differentiate components, ensuring that each fits perfectly into the PCB design.

- 4. Quantity Requirements: Stating the required number of each component is critical for inventory control and preventing production delays due to part shortages.

- 5. Mounting and Placement Information: Details on how and where to place components on the PCB are essential for the assembly process, ensuring accuracy and efficiency.

- 6. Packaging Types and Layer Specifications: Information on the physical packaging and layer placement of components is crucial for assembly, especially in complex, multilayer PCB designs.

- 7. Alternatives and Hierarchical Structure: Suggestions for substitute components and an organized BOM structure assist in smoother procurement and assembly processes.

- 8. Lifecycle Stages: Understanding each component’s phase in its lifecycle assists in effective project management, especially for new product introductions.

Addressing Bill of Materials (BOM) Challenges in PCB Assembly Quotations

Have you ever found yourself waiting on a quote for a PCB project, only to be held up by a single component needing confirmation? It’s a common scenario in the early stages of procurement. Those small details in a BOM, often overlooked, can cause significant delays and frustrations. Let’s talk about some of these familiar challenges and how to navigate them effectively.

H3: Is Component Substitution Acceptable in PCB Assembly Quotations?

In PCB assembly quotations, the need for component substitution can arise for several reasons, including high costs, discontinued items, or import-related delays.

To address this, it’s crucial to have a clear communication process with suppliers. For any potential substitutions, suppliers should be instructed to provide specification sheets of the alternative components for approval. This ensures that the functionality of the substituted parts aligns with the original requirements. Leveraging components from quality Chinese brands can be a viable strategy, as they often meet the required specifications at a more favorable price point, making this a common and practical solution in PCB assembly.

Why is Detailed Component Information Important in PCB Assembly Quotations?

The importance of detailed component information in PCB assembly quotations extends beyond mere descriptions. It encompasses the need for complete part numbers, as different suffixes can denote variations in packaging and other specifications. Additionally, including precise details about component packaging is crucial. This level of detail not only ensures accuracy in quotations but also aids in calculating assembly costs more effectively. Precise component information, like exact part numbers and packaging details, enables suppliers to provide more accurate quotes and helps in foreseeing potential assembly challenges, contributing to a smoother PCB assembly process.

How Important Is It to Specify Special Requirements for Components in a BOM?

Specifying special requirements for components in a BOM, such as backside mounting or ‘do not install’ instructions, is crucial. Clear indications prevent assembly errors and ensure that the PCB is manufactured as intended. Neglecting these details can lead to costly reworks and material waste, significantly impacting the project’s budget and timeline. Therefore, accurately documenting any unique component requirements is essential for efficient, cost-effective, and error-free PCB assembly.

Effectively managing the Bill of Materials (BOM) in PCB assembly quotations is all about preparation and thoroughness. By ensuring that your BOM is detailed and clear from the outset, you can significantly reduce the need for back-and-forth communication. This proactive approach not only streamlines the process but also enhances overall efficiency. In cases where uncertainties arise, remember that clarifications from your suppliers, along with providing any available physical samples or images, can swiftly resolve these issues, keeping your project on track with minimal delays.

Conclusion

Navigating through the complexities of a PCB project is a journey of precision and attention to detail, especially concerning the Bill of Materials. Remember, the cornerstone of a successful PCB assembly lies in thorough BOM preparation and streamlined communication. This approach doesn’t just prevent mishaps; it sets the stage for efficiency and triumph in your projects.

Looking for expertise in PCB assembly? Rowsum is here to help. We offer top-tier PCB manufacturing solutions tailored to your project’s specific needs. Get in touch with us at [email protected], and let’s work together to make your PCB project a standout success!