Introduction

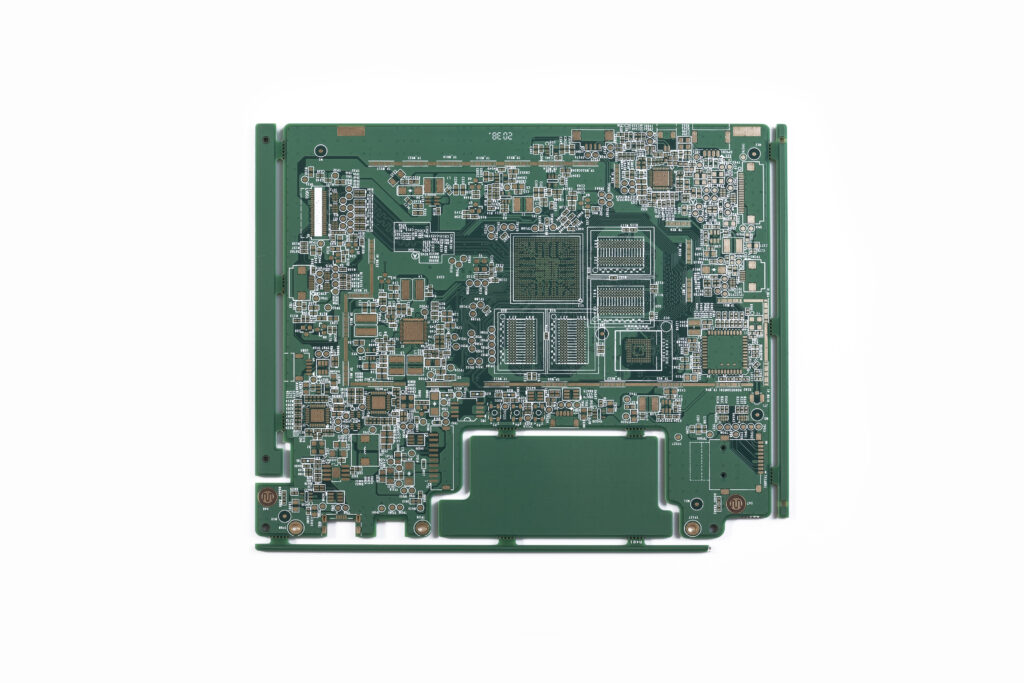

Have you ever wondered how the electronic devices we use daily are built? How the intricate circuits inside your smartphone or computer come to life? What goes into designing and manufacturing these complex systems? These questions often lead us to the fascinating world of Printed Circuit Boards (PCBs).

Understanding PCB Design and Manufacturing with Rowsum

PCB design and manufacturing is a meticulous process that involves creating a blueprint for electrical circuits, selecting the right materials, and assembling components to create a functional product. Rowsum, a leading PCB and PCBA manufacturer based in China, excels in this process. We specialize in delivering high-quality PCB products to clients worldwide, leveraging our automated production line for efficiency and cost-effectiveness.

Our commitment to quality, reliability, and customer service sets us apart in the industry. We believe in prioritizing our customers’ needs and providing solutions that align with their business goals. Stay with us as we delve deeper into the world of PCB design and manufacturing, and discover how Rowsum can help you navigate this complex landscape.

Step-by-Step Guide to PCB Design

Designing a Printed Circuit Board (PCB) is a complex process. It requires a deep understanding of electrical parameters, careful planning, and precise execution. Here, we break down the process into nine manageable steps:

Understanding Electrical Parameters

Before you start designing a PCB, it’s crucial to understand the electrical parameters of the system. These include current maximums, voltages, signal types, capacitance limitations, impedance characteristics, shielding considerations, and the type and location of circuit components and connectors.

A detailed net wire listing and schematic can provide a clear picture of these parameters. This understanding forms the foundation of your PCB design. Use simulation software to verify these parameters and ensure they meet the requirements of your design.

Creating the Schematic

The next step is creating the schematic. The schematic is the heart of any PCB design. It’s a diagram that represents the electrical connections and functions of the circuit.

Creating a schematic is one of the first steps in PCB design. It forms the basis for the subsequent layout process.

Designing the PCB Layout

Once the schematic is ready, it’s time to create the PCB layout. This is where a schematic capture tool comes in handy.

It allows you to develop a schematic with a software platform such as Mentor PADS®, Allegro, or Altium, showing exactly how your board will operate and where the components will be placed.

Defining Design Rules and Requirements

Design rules and requirements are largely dictated by standards and acceptability criteria from the IPC, the industry association for PCB and electronics manufacturing.

These standards provide guidelines for PCB manufacturing, ensuring that your design is compatible with manufacturing processes. Adhering to these standards is crucial for a successful PCB design.Tips: Use a design rule check (DRC) tool to verify that your design meets these standards.

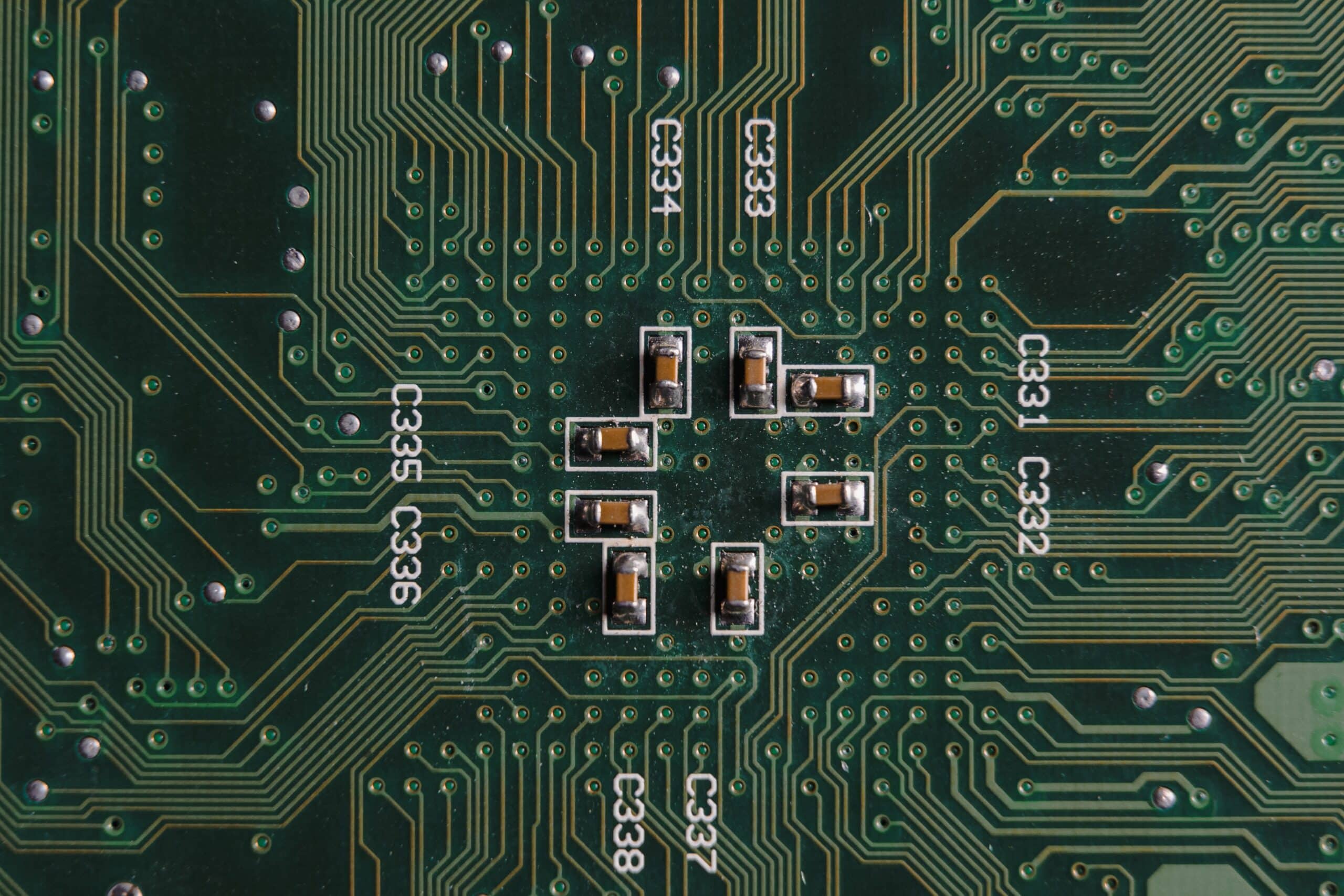

Component Placement and Drill Hole Insertion

The placement of components on the PCB is a critical step in the design process. It’s important to follow design and layout guidelines to ensure that components do not interfere with each other.

Use a component placement tool to optimize the placement of components and reduce the length of traces.

Once the components are placed, drill holes are inserted for connections. This step is crucial for the functionality of the PCB.

Routing the Traces

After placing the components and inserting drill holes, the next step is to route the traces. Traces are the paths that connect different components on the PCB.

Proper routing ensures efficient signal transmission and minimizes interference. This step is crucial for the performance of the PCB.

Adding Labels and Identifiers

Labels and identifiers are added to the layout to indicate where specific components will go on the board. These can be extremely helpful during the assembly process.

This step helps ensure that the PCB is assembled correctly and functions as intended.

Generating Design/Layout Files

The final step in the PCB design process is to generate the design/layout files. These files contain all the information about your PCB and are used for fabrication and assembly.

Typically, the files generated include:

- Gerber Files: These are standard files for PCB manufacturing. They contain information about the copper layers, solder mask, legend, and drill data.

- Drill Files: These files provide the locations, sizes, and shapes of all the holes to be drilled on the PCB.

- Pick and Place Files: These files are used during assembly to identify the locations and orientations of components on the PCB.

- Bill of Materials (BOM): This is a list of all the components to be placed on the PCB, including their specifications and reference designators.

- Assembly Drawings: These provide a visual guide for the assembly of the PCB, showing the locations of all components.

By generating these files, you ensure that your PCB design is fully documented and ready for manufacturing. This comprehensive documentation can help prevent errors during fabrication and assembly, ensuring a high-quality final product.

Best Practices in PCB Design

Designing a PCB is a complex process, but following best practices can ensure a smooth design process and a high-quality final product. Here are some of the best practices you should consider:

Choose a PCB Provider that Values Communication

Choosing a PCB provider that values open and constant communication is crucial. A provider like Rowsum, for instance, prioritizes customer needs and provides solutions that align with their business goals. Discuss everything you need or require for your project at the beginning of the design process. This can reduce the need for multiple extensive revisions and ensure that your PCB is properly designed from the start. With Rowsum, you can expect a partnership that fosters clear communication, ensuring a smooth design process and a high-quality final product.

Consider the Environment

Consider the environment in which the product has to function. Is the PCB designed for a non-extreme environment, such as a cell phone, or the highest of extremes, such as an explosion? Understanding the operating environment can help you choose the right materials and design strategies.

Use the Right Design Tools

Use the right design tools for your project. Tools like Mentor PADS®, Allegro, or Altium can help you create accurate schematics and layouts. They also offer features like design rule checks and auto-routing to streamline the design process.

Follow Design Standards

Follow design standards and acceptability criteria from the IPC, the industry association for PCB and electronics manufacturing. These standards provide guidelines for PCB manufacturing and ensure that your design is compatible with manufacturing processes.

Optimize Component Placement

Optimize the placement of components on the PCB. Use a component placement tool to ensure that components do not interfere with each other and to reduce the length of traces. This can improve the performance of the PCB and make the assembly process easier.

Generate Comprehensive Design/Layout Files

Generate comprehensive design/layout files, including Gerber files, drill files, pick and place files, a Bill of Materials (BOM), and assembly drawings. These files contain all the information about your PCB and are crucial for fabrication and assembly.

By following these best practices, you can streamline the PCB design process and ensure a high-quality final product. In the next section, we’ll discuss how Rowsum can help you implement these best practices and navigate the complexities of PCB design.

The Role of Materials in PCB Design

The materials used in PCB design play a critical role in the performance and reliability of the final product. Here, we delve into the importance of material selection and the common materials used in PCB design.

Importance of Material Selection

The selection of materials for a PCB is a crucial decision that can significantly impact the performance of the final product. The materials used can affect the PCB’s durability, conductivity, heat resistance, and other important characteristics. Therefore, it’s essential to choose materials that are suitable for the intended application of the PCB.

Common Materials Used in PCB Design

There are several materials commonly used in PCB design, each with its own advantages and considerations:

- FR-4: This is the most commonly used material for PCBs. It’s a glass-reinforced epoxy laminate material that is known for its durability and high performance.

- Polyimide: This material is used for flexible PCBs. It’s highly resistant to heat and is flexible, making it suitable for applications where the PCB needs to bend.

- Aluminum: Aluminum-backed PCBs are used for their excellent heat dissipation properties. They’re commonly used in LED lighting and power supply circuits.

- PTFE (Teflon): This material is used for high-frequency PCBs due to its low dielectric constant and low signal loss.

Choosing the right material for your PCB design is a complex decision that requires a deep understanding of the materials and their properties. At Rowsum, we can guide you through this process, helping you choose the best materials for your specific needs and ensuring a high-quality final product. In the next section, we’ll discuss Rowsum’s capabilities in PCB layout and how we can help you navigate the complexities of PCB design.

The Rowsum Advantage

When it comes to PCB design and manufacturing, Rowsum stands out from the competition. Here’s why:

High-Quality PCB Products

At Rowsum, we prioritize quality above all else. Our PCBs are meticulously designed and manufactured to meet the highest standards. We use top-quality materials and follow strict quality control processes to ensure that our products are reliable and durable.

Efficient and Cost-Effective Production

Thanks to our automated production line, we’re able to deliver products efficiently and cost-effectively. We understand that time and cost are crucial factors for our clients, and we strive to provide solutions that are both high-quality and affordable.

Commitment to Customer Service

We believe in putting our customers first. Our team is always ready to provide technical support and answer any questions you may have. We value open communication and work closely with our clients to understand their needs and provide solutions that align with their business goals.

Expertise in PCB Design and Manufacturing

With years of experience in the industry, we have the expertise to handle complex PCB designs and manufacturing processes. We stay up-to-date with the latest technologies and industry standards to provide our clients with the best possible solutions.

Global Reach

Based in China, we serve B2B clients in various countries, including North America, Europe, Southeast Asia, and Africa. Our global reach allows us to understand and cater to the diverse needs of our clients. In addition, we have offices in the United States and Hong Kong, and we have appointed local business managers to provide better service to our clients in these regions.

Choosing Rowsum as your PCB provider means choosing quality, efficiency, and excellent customer service. We’re committed to helping our clients succeed and providing solutions that exceed expectations. In the next section, we’ll delve into the specifics of PCB design and how Rowsum can help you navigate this complex process.

Conclusion

PCB design is a complex process that requires a deep understanding of electronics, materials, and manufacturing processes. By following the steps and best practices outlined in this guide, you can navigate this process more effectively and create high-quality PCBs.

However, even with the best practices, PCB design can still be a challenging task. That’s where Rowsum comes in. With our commitment to quality, efficient production processes, excellent customer service, and global reach, we can help you navigate the complexities of PCB design and manufacturing. Whether you’re a seasoned professional or a beginner in the field, Rowsum is here to support you every step of the way.

FAQs

Q1: What is the most important factor to consider in PCB design?

The most important factor to consider in PCB design is the intended application of the PCB. This will determine the materials used, the layout of the components, and other design considerations.

Q2: What are the common materials used in PCB design?

Common materials used in PCB design include FR-4, Polyimide, Aluminum, and PTFE (Teflon). The choice of material depends on the intended application of the PCB.

Q3: How can Rowsum help with my PCB design process?

Rowsum can provide guidance throughout the PCB design process, from initial concept to final production. We offer high-quality PCB products, efficient and cost-effective production, excellent customer service, and expertise in PCB design and manufacturing.

Q4: Does Rowsum have a minimum order quantity (MOQ)?

No, Rowsum understands the importance of project validation and is committed to growing with our clients. That’s why we offer no minimum order quantity, accommodating projects of all sizes.

Q5: How does Rowsum ensure the quality of its products?

Rowsum prioritizes quality above all else. We use top-quality materials and follow strict quality control processes to ensure that our products are reliable and durable.

Get Access Now: www.rowsum.com