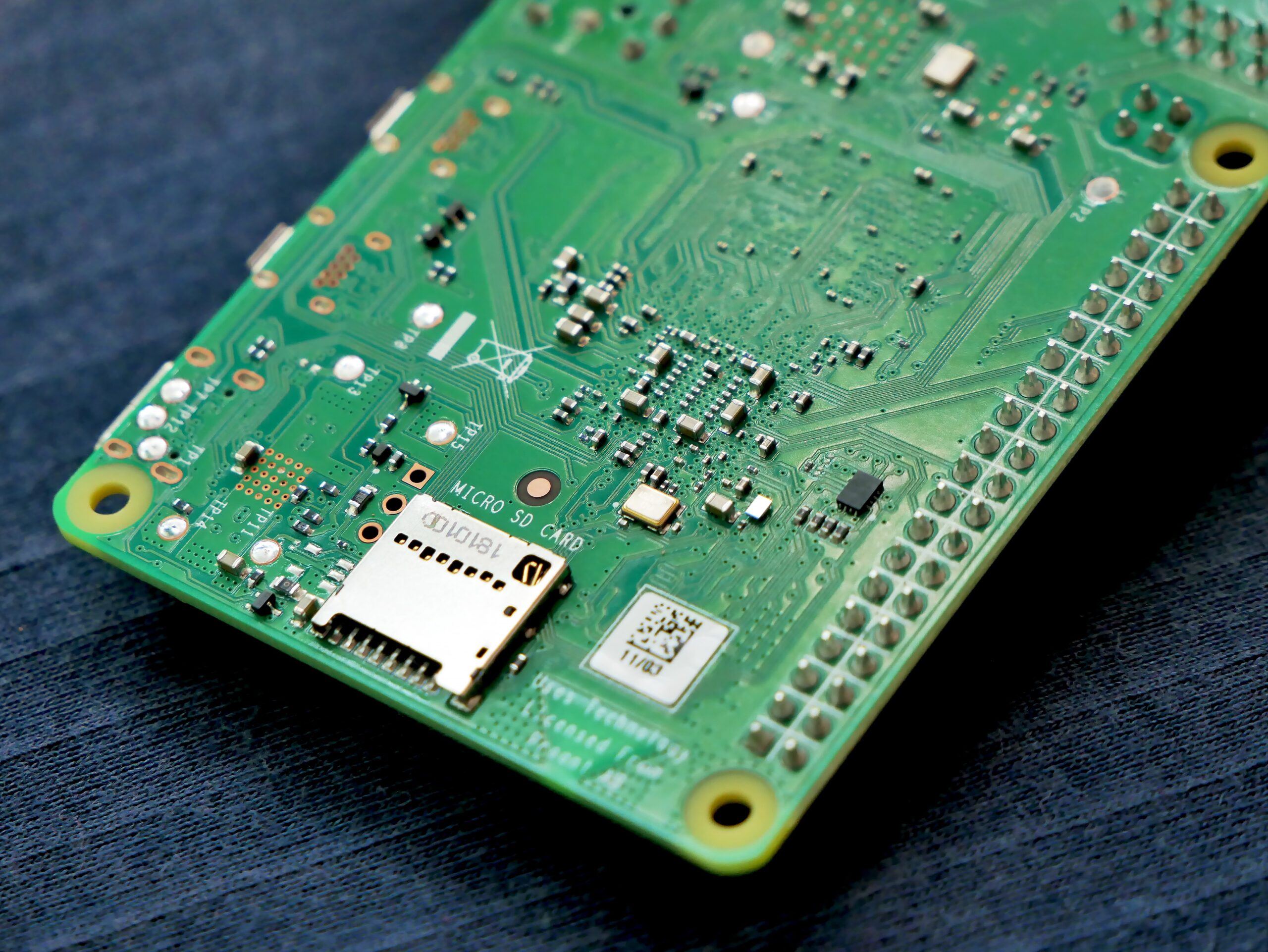

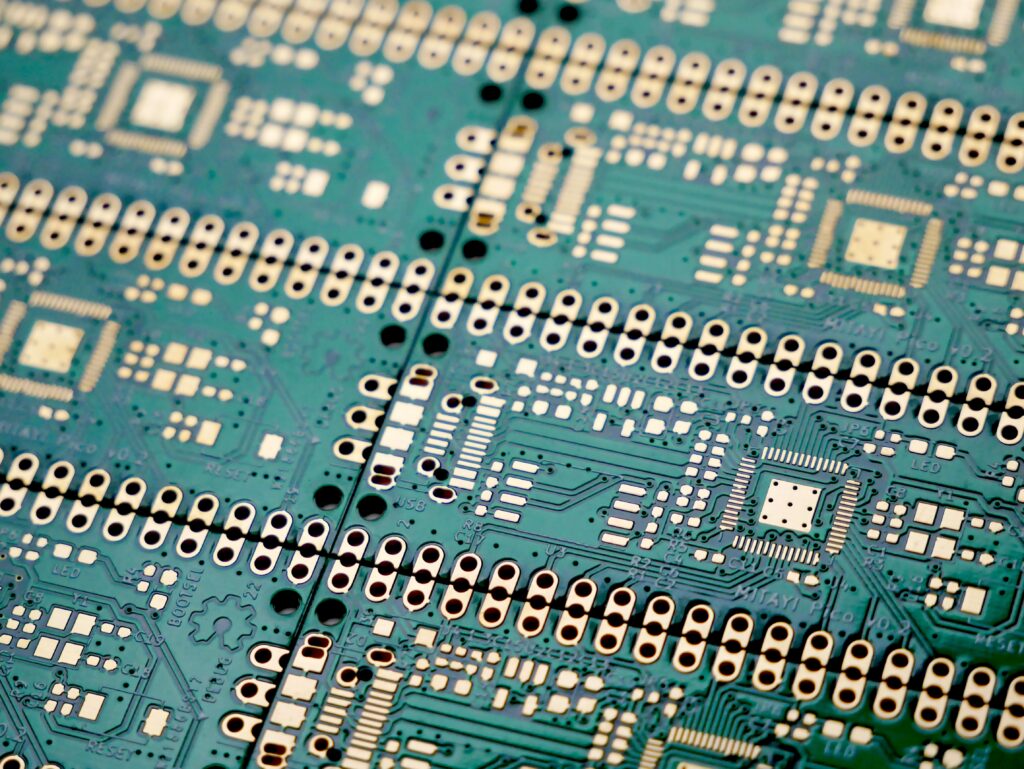

When it comes to PCB manufacturing, one important factor that often gets overlooked is copper weight. Copper weight refers to the thickness of the copper layer on a PCB, which can vary depending on the specific design requirements of the board. In this blog post, we’ll explore the concept of copper weight and its significance in PCB manufacturing.

What is Copper Weight?

Copper weight refers to the thickness of the copper layer on a PCB, typically measured in ounces per square foot (oz/ft²). The most common copper weights for PCBs are 1 oz/ft² and 2 oz/ft², although other weights are also available depending on the specific requirements of the design.

Why is Copper Weight Important?

Copper weight is an important consideration in PCB manufacturing because it can affect the overall performance and functionality of the board. A higher copper weight can increase the current carrying capacity of the traces on the board, which can be beneficial for high power applications. It can also help to reduce the resistance of the traces, which can improve the signal integrity of the board.

On the other hand, a lower copper weight can reduce the overall cost of the board and make it easier to manufacture, especially for boards with smaller trace widths and spacing. However, it may not be suitable for high power or high-speed applications, where a thicker copper layer is required.

Different Copper Weights and their Effects

As mentioned earlier, the most common copper weights for PCBs are 1 oz/ft² and 2 oz/ft². Here’s a closer look at how these different copper weights can affect the performance and functionality of the board:

1 oz/ft² Copper Weight:

·Suitable for low power applications

·Can handle up to 3A of current for 1/2″ trace width

·Easy to manufacture

·Lower cost compared to 2 oz/ft²

2 oz/ft² Copper Weight:

·Suitable for high power applications

·Can handle up to 6A of current for 1/2″ trace width

·Better signal integrity due to lower trace resistance

·Higher cost compared to 1 oz/ft²

Other Copper Weights:

Other copper weights are also available, such as 0.5 oz/ft² and 3 oz/ft². These are less commonly used and are typically reserved for specific design requirements.

In conclusion, copper weight is an important factor to consider in PCB manufacturing. The right copper weight can affect the overall performance and functionality of the board, and should be chosen based on the specific design requirements. By understanding the concept of copper weight and its effects, PCB designers can make informed decisions and create high-quality boards that meet the needs of their applications.