In the dynamic world of electronics, understanding the building blocks of our devices is crucial. Two terms often emerge at the forefront of this discussion: PCB and PCBA. But what do they mean, and how do they differ?

PCB vs. PCBA: A Brief Overview

A PCB, or Printed Circuit Board, is the foundational board that provides the layout for electronic components. In contrast, PCBA stands for Printed Circuit Board Assembly, which is the process of placing and soldering these components onto the PCB. While a PCB is like an empty stage, the PCBA is the complete show, with all actors (components) in place, ready to perform their electronic functions.

Breaking Down the Basics

Electronics, in their myriad forms, rely on intricate designs and precise assemblies. At the heart of these designs are the PCB and PCBA, two terms that are often used interchangeably but have distinct meanings and roles. Let’s break down these foundational elements.

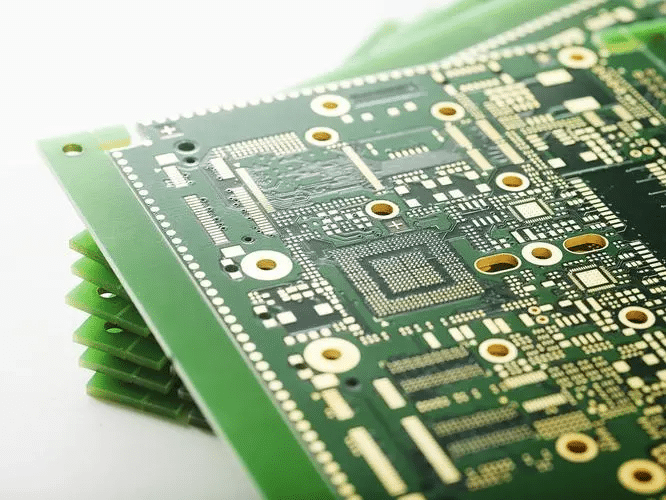

What is a PCB (Printed Circuit Board)?

A PCB, or Printed Circuit Board, is essentially the physical board made of non-conductive materials, often fiberglass or composite epoxy. On this board, conductive pathways or tracks are etched or printed, which guide electricity to various components. It serves as the bedrock, providing the layout and connections but without any active components.

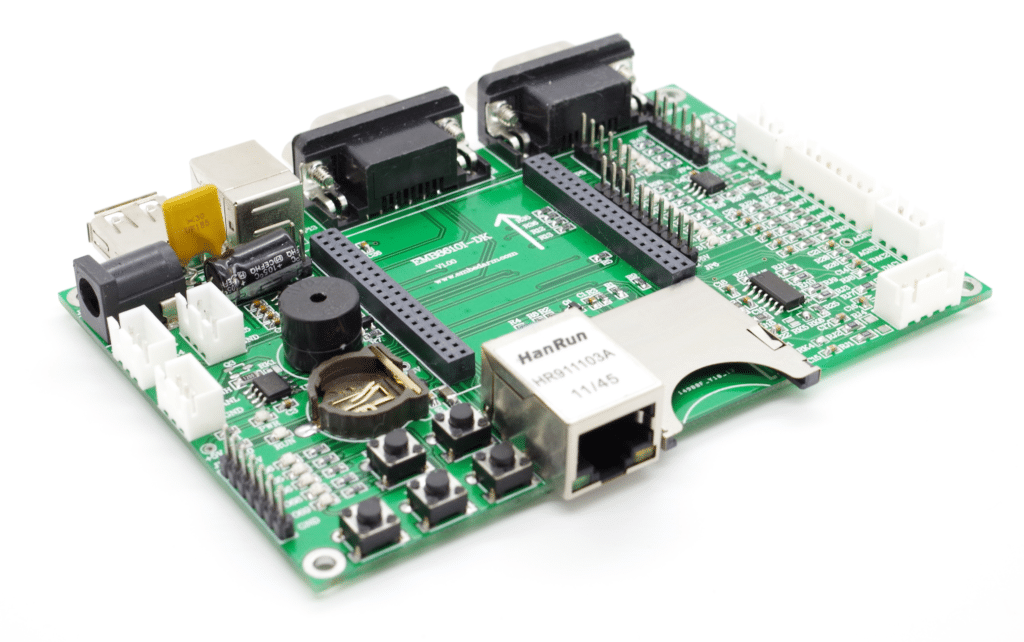

Exploring PCBA (Printed Circuit Board Assembly)

The Fundamental Differences Between PCB and PCBA

While the PCB is the foundational layout, the PCBA is the culmination of that layout fused with its requisite components. In simple terms:

- PCB: The physical board with conductive pathways but no electronic components.

- PCBA: The board plus all its electronic components, fully assembled and ready for use.

Understanding this distinction is crucial for anyone involved in electronics, whether you’re designing a new gadget, overseeing production, or simply curious about the inner workings of your devices.

The Intricacies of PCBA: Beyond the Basics

Electronics have become an integral part of our daily lives, from the smartphones we can’t live without to the smart appliances that make our homes more efficient. But behind these innovations of modern technology lies a complex world of components and connections, governed by the principles of PCBA. Let’s dive deeper into this intricate realm.

Components of PCBA

Every electronic device, from the simplest LED flashlight to the most advanced AI-driven gadget, is powered by a myriad of components. Here’s a closer look at some of these essential elements:

- Resistors: These tiny components control the flow of electricity, ensuring that it moves at the right pace, much like traffic signals on a busy road.

- Capacitors: Think of capacitors as short-term energy banks. They store and release energy, stabilizing power supply and filtering out any noise.

- Transistors: The switches of the electronic world. They can amplify or switch electronic signals, forming the foundation of most electronic functions.

- Integrated Circuits (ICs): These are the command centers of our devices. Housing millions of transistors, resistors, and capacitors, ICs perform complex tasks, driving the miniaturization trend in electronics.

The Significance of Each Component

In the digital age, the components within our devices are more than just technical marvels; they shape our experiences:

- Reliability: Components ensure our devices operate consistently, from life-saving medical equipment to our daily-use smartphones.

- Miniaturization: Thanks to components like ICs, devices have become smaller, paving the way for innovations like wearable tech.

- Efficiency: Efficient components translate to longer battery life and reduced energy consumption.

- Innovation: As components evolve, they drive technological advancements, from AI to augmented reality.

The Synergy in PCBA

While individual components play pivotal roles, it’s their combined efforts that make our devices come alive:

- Unified Purpose: Each component in PCBA contributes to the device’s overall function, be it clear audio output or sharp display.

- Efficient Communication: Components communicate, ensuring synchronized operations, forming the backbone of any electronic device.

- Adaptive Functioning: Modern PCBAs can adapt. If one pathway is blocked, the circuitry finds alternative routes, ensuring uninterrupted functionality.

- Peak Performance: When components collaborate, devices operate efficiently, ensuring faster speeds and enhanced user experience.

In conclusion, the world of PCBA is a testament to human ingenuity. It’s where individual components, each a marvel in its own right, come together to create the devices that power our modern world.

One-Stop Services: Rowsum’s Pledge to Excellence

In the intricate realm of electronics manufacturing, the concept of one-stop services stands as a beacon of efficiency and reliability. As a leading PCB&PCBA manufacturer based in China, we at Rowsum champion this approach, offering a comprehensive range of services tailored to the diverse needs of businesses across various industries.

Comprehensive Services Under One Roof

Our integrated approach to the one-stop service model ensures:

- Direct Factory Pricing: By eliminating middlemen markups.

- Seamless Communication: With dedicated project managers at the helm.

- Rapid Turnarounds: Achieving sample production times as swift as 24 hours.

Unwavering Commitment to Quality

Our dedication to quality shines through in:

- State-of-the-Art Equipment: Advanced manufacturing tools and stringent processes guarantee product excellence.

- Certifications: We proudly hold certifications including ISO 9001, ISO 14001, UL, RoHS, and REACH, showcasing our adherence to global standards.

- Impressive Production Capacity: Our 50,000 square meter monthly production capacity ensures timely deliveries, no matter the order size.

Global Presence with a Local Touch

With strategic offices in the United States and Hong Kong:

- Enhanced Communication: We bridge time zones and cultural nuances for smoother interactions.

- Building Trust: Clients recognize us as more than just a service provider; we’re a trusted partner in their journey to success.

Tailored Solutions for Every Client

Whether it’s tech startups in Silicon Valley or large electronics manufacturers in Germany:

- Adaptable Services: Our offerings, including a no MOQ policy, are designed to cater to the unique needs of every client.

- Consistent Quality: A hallmark that businesses, big or small, can rely on.

Growing Side by Side

Central to our ethos is the belief in mutual growth. With frequent promotions for PCB prototypes, we’re invested in building long-term relationships, ensuring that as we flourish, our clients do too.

Conclusion

The distinction between PCB and PCBA is pivotal in the realm of electronics. A PCB represents the foundational board with conductive pathways, while PCBA embodies that board, complete with all its electronic components. This differentiation isn’t just about terminology; it’s central to the entire electronics manufacturing process. By understanding the significance of each component and their collective harmony, we pave the way for the creation of reliable and top-tier electronic devices.

At Rowsum, we’re more than just manufacturers; we’re your dedicated partners in electronics. We ensure your projects surpass expectations. For more insights or inquiries, reach out to us at [email protected].